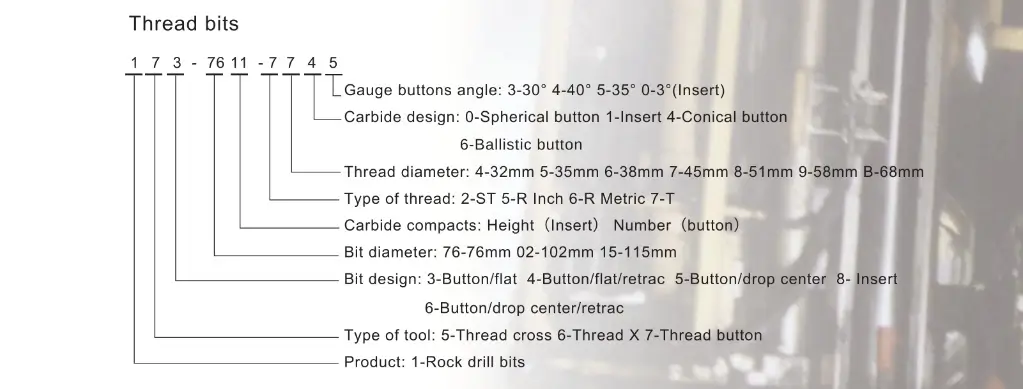

R32 Thread Button Bit Description

RockHound R32 Threaded Rock Drill Bits are engineered for medium to hard rock formations, providing a perfect balance between drilling speed and service life. By utilizing high-grade 45CrNiMo1V steel and premium tungsten carbide inserts, these bits ensure maximum impact energy transfer to the rock.

Whether you need the stability of Cross/X-type insert bits or the high efficiency of Thread Button bits, RockHound R32 series offers various diameters (48mm to 60mm) to match your specific drifter and drilling conditions.

Features

RockHound R32 drill bits combine advanced heat treatment processes and geometric design, offering the following core advantages:

Premium Material: Forged from 45CrNiMo1V high-strength alloy steel for excellent fatigue resistance and impact toughness.

Superior Carbide Quality: Equipped with high-wear-resistance tungsten carbide buttons/inserts to maintain sharpness longer.

Optimized Flushing: Scientifically designed flushing holes ensure efficient debris removal and prevent over-heating.

Precision Threading: Standard R32 threads ensure a tight, reliable connection with the drill rod, reducing energy loss.

Versatile Designs: Available in Button, Cross, and X-type configurations to handle various geological conditions from fractured to solid rock.

- Wear Resistance: Special surface treatment processes (such as shot peening) significantly increase the hardness of the metal surface.

Specification

| Thread bit, Insert | D (Diameter) | Insert (H×T) | Thread | Product Code | Weight (kg) | |

|---|---|---|---|---|---|---|

| mm | inch | |||||

| Cross Type Insert Bits | ||||||

| Cross | 50 | 2 | 16×10 | R32 | 158-5016-5410 | 1.0 |

| Cross | 55 | 2 1/6 | 16×10 | R32 | 158-5516-5410 | 1.2 |

| Cross | 60 | 2 3/8 | 16×10 | R32 | 158-6016-5410 | 1.2 |

| X Type Insert Bits | ||||||

| X | 55 | 2 1/6 | 16×10 | R32 | 168-5516-5410 | 1.2 |

| X | 60 | 2 3/8 | 16×10 | R32 | 168-6016-5410 | 1.2 |

| Thread bit, Button | D (Diameter) | Buttons (No×Size.mm) | Gauge Button Angle | Thread | Product Code | Weight (kg) | ||

|---|---|---|---|---|---|---|---|---|

| mm | inch | Gauge | Centre | |||||

| Button Bits (R32) | ||||||||

| Button | 48 | 1 7/8 | 6×10 | 3×9 | 35° | R32 | 173-4809-5465 | 0.9 |

| Button | 51 | 2 | 6×10 | 3×9 | 35° | R32 | 173-5109-5465 | 1.1 |

| Button | 55 | 2 1/6 | 6×11 | 3×9 | 35° | R32 | 173-5409-5465 | 1.1 |

| Button | 57 | 2 1/4 | 6×11 | 3×10 | 35° | R32 | 173-5709-5465 | 1.2 |

Applications

Rhdrill R32 Thread Button Bits are designed for various complex medium-hard to hard rock formations, with applications including:

Mining: Underground mining, production drilling, and rock bolting.

Quarrying: Stone extraction and bench drilling.

Construction: Foundation reinforcement and road construction.

Tunneling: Drift and tunnel excavation.

Field Test Report:R32 Drill Bits at Iron Mine

-

Specification: 9-Button, R32 Thread.

-

Quantity: 5 Pieces

| Serial No. | Service Life / Footage (m) | Failure Mode |

|---|---|---|

| 1# | 348 | Normal Wear |

| 2# | 352 | Normal Wear |

| 3# | 363 | Normal Wear |

| 4# | 345 | Normal Wear |

| 5# | 356 | Normal Wear |

| Average Service Life: 352.8 m [Data Source: 33] | ||

How To Maintenance

Regrinding: Periodically check the carbide buttons. Regrind the buttons when they reach about 1/3 of their diameter in wear to prevent “snake skin” or bit body failure.

Cleaning: Ensure the flushing holes and R32 threads are cleaned of debris before each use.

Lubrication: Use proper thread grease to prevent galling and ensure easy decoupling.

Storage: Store in a dry, rust-protected environment to maintain the integrity of the 45CrNiMo1V steel.

FAQ

- Ballistic buttons: Suitable for drilling soft or medium-hard rock, offering extremely fast penetration speed, but with faster wear.

- Spherical buttons: Suitable for extremely hard and highly abrasive formations, more durable, and with a lower failure rate.

Common causes of problems include: improper pressure adjustment (leading to overheating), clogged flushing holes (leading to repeated wear), or loose thread connections. Regularly checking the wear condition of the drill bit teeth (sharpening) can significantly extend the drill bit's lifespan.

Yes. RockHound R32 bits are manufactured to international standard ISO specifications. The precision-machined R32 threads ensure seamless compatibility with all major brands of top hammer drill rods and drifters (like Atlas Copco, Sandvik, or Epiroc systems).

It is available. The Retrac design helps to easily retract the drill rod in fractured rock formations, reducing the risk of drill bit loss.

The choice depends primarily on the rock formation:

R32 Button Bits: Best for medium to hard rock. They offer faster penetration rates and are more efficient in homogenous rock because the tungsten carbide buttons provide a higher impact force.

R32 Cross Bits: Ideal for fractured or fissured rock. The cross-design prevents the bit from "plugging" or getting stuck in cracks, providing better hole straightness in difficult geological conditions.

45CrNiMo1V is a premium high-strength alloy steel specifically chosen for its superior fatigue resistance and impact toughness. Compared to standard steel, it can withstand the high-frequency impacts of top hammer drilling without premature body breakage, ensuring a significantly longer service life and better ROI for your project.

To maintain maximum efficiency, you should regrind your bits when:

The penetration rate drops significantly.

The carbide buttons show a "flat" surface (when the flat area reaches about 1/3 of the button diameter).

You notice "snake skin" (fine cracks) on the surface of the tungsten carbide. Regular maintenance prevents the bit body from over-stressing and failing.