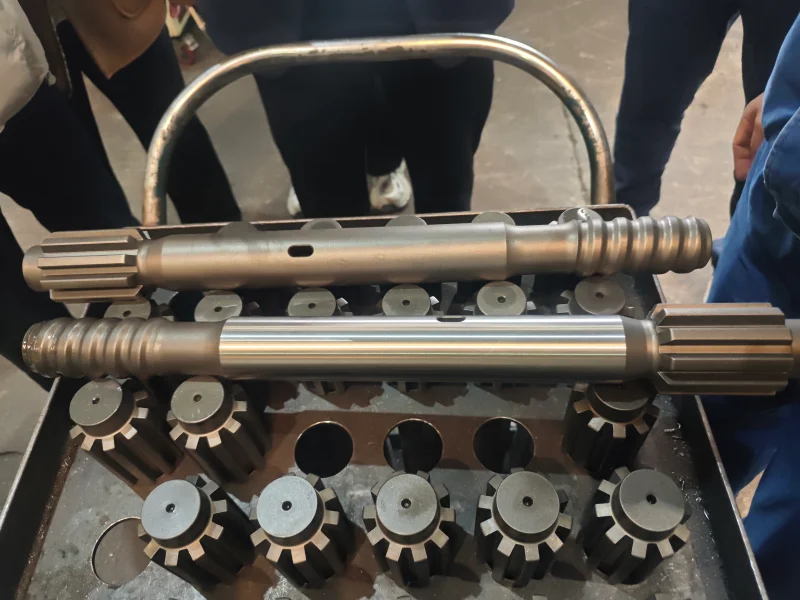

What Rock Drill Shank Adapter Is?

The shank adapter is a critical transmission component in rock drilling systems, connecting the rock drill to the drill bit. It directly withstands high-frequency impacts, torque, and fatigue loads. The quality of its manufacturing process directly determines the product’s service life, energy transfer efficiency, and the stability of the entire drilling system.

What Makes A High-quality Shank Adapter?

At RockHound, we utilize premium ZK22CrNi3Mo alloy steel and a rigorous 9-step manufacturing process to ensure maximum fatigue strength and service life.

RockHound will introduce the complete production process of rock drill shank adapters, from raw material selection to final packaging, helping customers gain a comprehensive understanding of how high-quality shank adapters are manufactured.

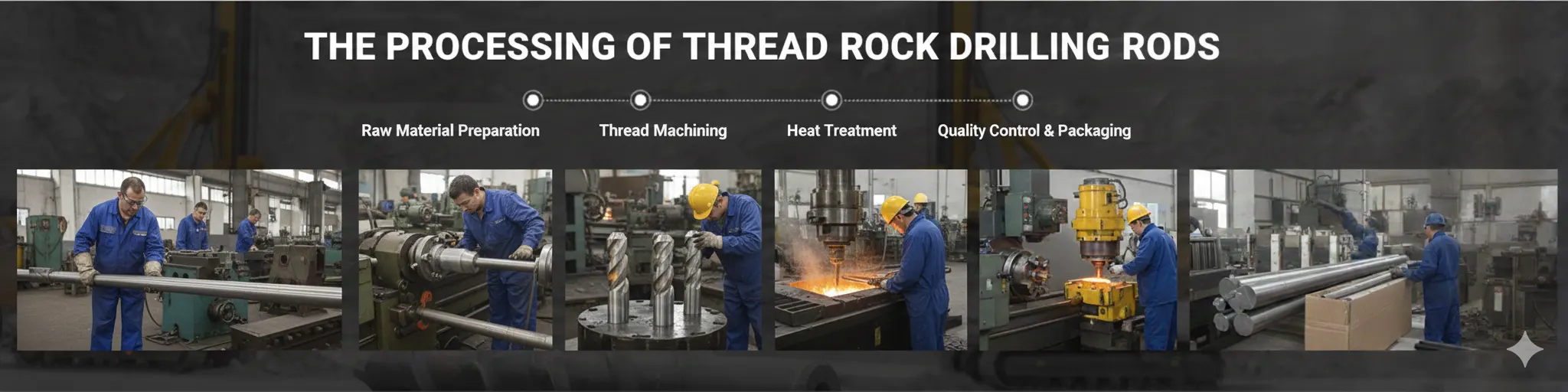

Step1. Raw Material Selection

Material Grade: ZK22CrNi3Mo

ZK22CrNi3Mo is a low-carbon alloy structural steel specifically developed for rock drilling tools, possessing the following advantages:

- Excellent hardenability

- High impact resistance

- Superior fatigue strength

- Stable carburizing performance

This material is widely used in high-impact rock drilling tools such as Shank Adapters, Drill Rods, and Coupling Sleeves.

Step2. Cutting & Blank Preparation

RockHound machining process is where structural integrity meets precision. We maintain a strict tolerance of within 0.05mm.

Cutting & Shaping: Raw bars are precision-cut to specified lengths and turned using advanced CNC machines.

Flushing Hole Expertise: We drill concentric flushing holes and side flushing holes. Unlike standard designs, our internal water channels are strategically engineered to optimize flow without compromising the shank’s structural wall.

Chamfered Splines (RHdrill Competitive Edge): While many manufacturers leave splines with sharp right angles, we apply a specialized chamfering process. This reduces stress concentration and prevents premature chipping of the rock drill’s rotation chuck.

Although this process is simple, it is crucial for dimensional consistency and control of internal material stress.

Step3. Advanced 0.02mm CNC Machining

Machining is the core process that determines the geometric accuracy and performance of the drill bit.

Main machining processes include:

3.1 External Turning

Precision turning of the rod body outer diameter

Ensuring concentricity and straightness

3.2 Central Hole Machining

Drilling of high-precision concentric holes

Ensuring stable energy transfer and avoiding eccentric impact

3.3 Flushing Holes Machining

Side Water Holes

Through Water Hole

The length of the through water hole is longer than the side water holes, but does not extend to the end, ensuring efficient cooling and slag removal.

3.4 Spline Machining

High-precision spline forming

All splines are chamfered

Effectively reduces stress concentration

Extends service life

Compared with some products using right-angle splines, the chamfered design significantly improves impact resistance.

3.5 End Face Finishing

Overall machining accuracy of the drill bit is controlled within ±0.05 mm

Ensuring stable cooperation with the rock drill and no abnormal vibration

Step4. Carburizing Heat Treatment

The shank end utilizes the same carburizing process principles as rock drilling rods:

High surface hardness (Wear Resistance)

Core maintains toughness (Impact Toughness)

Performance advantages after carburizing:

- Excellent wear resistance

- Strong fatigue and impact resistance

- Significantly extended service life

This is a crucial process indispensable for high-end shank adapters.

20-Hour Deep Carburization

In the world of rock drilling, “time in the furnace” equals “life in the hole.” While the industry average for heat treatment is only 8 to 12 hours, our premium rods undergo a rigorous 20-hour deep carburization cycle.

This extended process isn’t just about extra time; it’s about precision chemistry. By doubling the treatment duration, we achieve:

Deeper Case Hardness: A significantly thicker carburized layer that stands up to the most abrasive rock formations.

Optimized Carbon Gradient: A smoother transition from the hard outer shell to the tough, ductile core. This prevents the “brittle snapping” common in cheaply treated rods.

Maximum Fatigue Resistance: Our 20-hour cycle allows for superior stress relief and molecular stabilization, drastically reducing your “Cost per Meter” (CPM).

The Bottom Line: We invest more in electricity, gas, and time so that you spend less on replacements and downtime.

Comparison with Common Manufacturers

Other manufacturers often complete the carburizing process within 10 hours, while we employ a strictly controlled 20-hour carburizing cycle to ensure the stability of the molecular structure. This allows for an effective carburized layer depth of 0.6 mm to 1.2 mm, enabling the welding electrode to withstand millions of impacts without breaking.

| Technical Specifications | Standard Industry Process (8-13h) | RHdrill Premium 20-Hour Process | Performance Advantages & Value Addition |

|---|---|---|---|

| Effective Case Depth | 1.0mm – 1.5mm | 2.0mm – 3.0mm+ | Doubled or deeper case depth significantly extends wear-resistance and service life in abrasive rock drilling conditions. |

| Carbon Gradient Transition | Steep gradient; prone to peeling/delamination under impact. | Gentle gradient; high bonding strength | Eliminates abrupt stress risers between hardened case and tough core → superior resistance to chipping, spalling, and delamination. |

| Core Microstructure | Incomplete transformation; average toughness. | Refined grain structure; high strength & toughness | Balances extreme surface hardness with excellent impact fatigue resistance and ductility in demanding geological environments. |

| Internal Bore Fatigue Resistance | Prone to micro-cracks under cyclic high pressure. | Optimized internal stress distribution | Greatly reduces crack initiation and propagation from bore to outer surface, improving reliability in high-pressure flushing applications. |

| Expected Service Life | 100% (Industry Baseline) | 40% – 60% Increase | Proven extended performance in ultra-hard rock formations, complex geology, and high-abrasion drilling → lower cost per meter drilled. |

| Manufacturing Cost & Input | Lower energy, gas, and time requirements. | High Investment (Electricity, Gas, Extended Time) | Conclusion: Premium long-cycle carburizing/heat treatment sacrifices short-term cost for maximum durability, lowest total drilling cost, and highest uptime. |

Step5. Shot Blasting

Surface treatment using a shot blasting machine:

- Removes scale and micro-burrs

- Cleans surface residues

- Improves surface adhesion

Provides an ideal foundation for subsequent anti-corrosion treatment and surface finishing.

Step6. Surface Finishing

The central rod undergoes a fine surface treatment:

- Improves appearance consistency

- Enhances surface finish

- Surface accuracy can reach 0.01 mm

This not only improves the product’s aesthetics but also helps reduce assembly wear.

Step7. Anti-Corrosion Treatment

RockHound offer various corrosion protection solutions, among which wax dipping is highly recommended:

7.1 Wax Dipping

- Forms a uniform anti-corrosion layer on the surface

- Provides corrosion protection for internal holes as well

- Suitable for long-distance transportation and long-term storage

7.2 Black Painting

- Conventional anti-rust solution

- Meets general storage and usage requirements

8. Marking & Customization

Customer-specified marking is supported.

Marking size: 100 mm × 100 mm

Marking is an additional service with extra charges.

Brand, model, or batch information can be customized according to customer requirements.

9. Packaging

To ensure your tools arrive in mint condition, we use a two-tier packaging system:

- Individual packaging: Blue plastic protective case

- Outer packaging: Wooden crate with overall reinforcement

Ensuring safety and rust prevention during transportation

Conclusion

From material selection, precision machining, carburizing heat treatment, to corrosion protection and packaging, every step of the process directly affects the final performance of the Shank Adapter. A high-standard production process is crucial for ensuring drilling efficiency and reducing equipment failure rates.

Why Choose RockHound Shank Adapters?

By focusing on material purity, 0.05mm machining precision, and chamfered spline geometry, our rock drill tools deliver a lower cost-per-meter drilled.

- Premium Alloy Steel: We use high-strength alloy steel combined with advanced carburizing heat treatment to ensure maximum surface hardness and core toughness.

- Seamless OEM Compatibility: Our shank adapters are designed to be 100% interchangeable with major brands like Atlas Copco (Epiroc), Sandvik, Furukawa, and Montabert.

- Optimal Energy Transfer: Engineered for high-frequency impact, RockHound shanks minimize energy loss, ensuring every blow from the rock drill reaches the bit with maximum force.

- Extended Service Life: Thanks to our rigorous quality control and precision thread machining, we reduce thread wear and prevent premature breakage, lowering your cost per meter.

Would you like a custom quote or a technical data sheet for your specific rock drill model? [Contact Our Engineering Team Today]