Test Period

July 2025 – August 2025

Test Personnel

Technician: Mr. Li

Test Objectives

Market Expansion.

Continuous improvement of product quality.

Test Unit & Location

- Test Unit: [Certain] Iron Mine (Hebei).

Test Locations (Levels):

-540m Level (S4-JD-8)

-540m Level (S3-JD-10)

-540m Level (S6-JD-9)

Test Conditions

1. Rock Conditions

Protodyakonov Hardness Coefficient: f13 ~ f15

Corresponding Compressive Strength (UCS): 130 – 150 MPa

(Note: Based on the standard conversion $\sigma_c \approx 100 \times f \text{ kg/cm}^2 \approx 10 \times f \text{ MPa}$, rock with $f=13\text{-}15$ is classified as hard to very hard rock.)

2. Drilling Equipment & Parameters

Jumbo (Drilling Rig): Epiroc (Atlas Copco) Boomer 281

Rock Drill (Drifter) Model: COP 1838HD+

Drilling Parameters:

Feed Pressure (Propulsion): 75–80 bar

Percussion Pressure (Impact): 180 bar

Rotation Pressure: 190 bar

Flushing Water Pressure: 10–12 bar

Test Products & Data

1. Product A: MF Drill Rod (Speedrod)

Specification: ZK23CrNi3Mo H35×4305-T38/R32 (Hex 35mm, Length 4305mm)

Quantity: 8 Pieces

| Serial No. | Service Life / Footage (m) | Failure Mode |

|---|---|---|

| 1# | 3529 | Breakage at Small End Thread (Bit End) |

| 2# | 3753 | Breakage at Small End Thread (Bit End) |

| 3# | 3478 | Breakage at Small End Thread (Bit End) |

| 4# | 3389 | Breakage at Small End Thread (Bit End) |

| 5# | 3645 | Breakage at Small End Thread (Bit End) |

| 6# | 3725 | Breakage at Small End Thread (Bit End) |

| 7# | 3712 | Breakage at Small End Thread (Bit End) |

| 8# | 3549 | Breakage at Small End Thread (Bit End) |

| Average | 3597.5 m | Breakage at Small End Thread (Bit End) – 100% of samples |

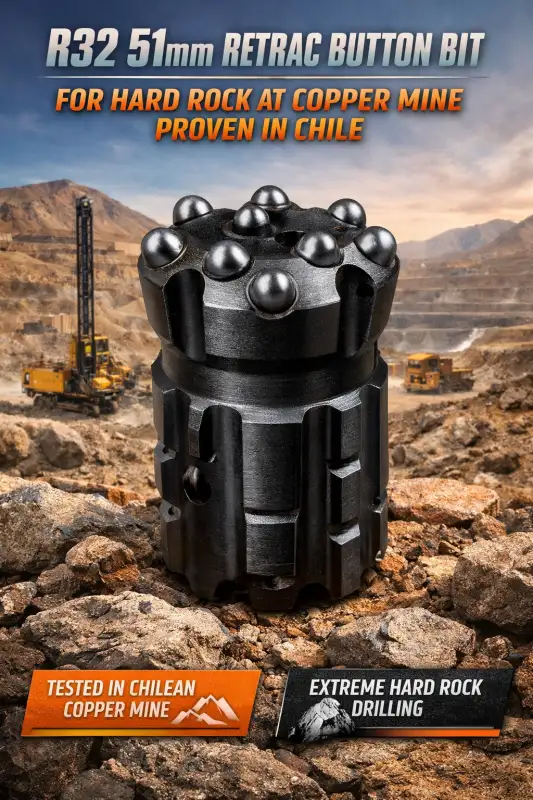

2. Product B: Threaded Button Bit

Specification: 9-Button, R32 Thread.

Quantity: 5 Pieces

| Serial No. | Service Life / Footage (m) | Failure Mode |

|---|---|---|

| 1# | 348 | Normal Wear |

| 2# | 352 | Normal Wear |

| 3# | 363 | Normal Wear |

| 4# | 345 | Normal Wear |

| 5# | 356 | Normal Wear |

| Average Service Life: 352.8 m [Data Source: 33] | ||