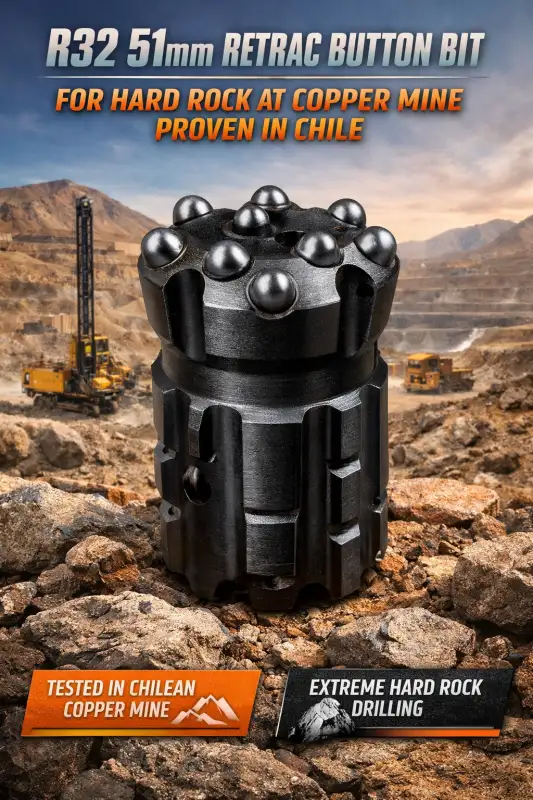

This report details the field performance and technical analysis of the R32 51mm Retrac Button Bit tested at the Copper Mine in Chile.

Geological Conditions and Rock Mechanics

The drilling site presented extremely challenging conditions, characterized by high abrasivity and compressive strength.

| Parameter | Typical Range | Technical Observation |

|---|---|---|

| Unconfined Compressive Strength (UCS) | 80 – 250 MPa | Extremely hard rock formations; values commonly exceed 180 MPa in granodiorite and similar intrusive rocks – requires premium carbide grades and optimized button shapes for efficient drilling |

| CERCHAR Abrasivity Index (CAI) | > 4.0 | High quartz content and extreme abrasiveness; demands high-wear-resistant spherical or conical buttons and frequent regrinding to maintain ROP and extend bit life |

| Rock Mass Rating (RMR) | 45 – 75 | Medium to good rock mass quality; suitable for standard to retrac skirts depending on fracture frequency and stability |

| Rock Quality Designation (RQD) | 50% – 90% | Higher in massive competent zones, lower near faults or joints; influences choice of face design (Drop Center for fractured zones, Convex/Flat for massive rock) |

| Geological Strength Index (GSI) | 50 – 80 | Moderate to high rock mass strength; dependent on fracture density and infill cohesion – affects overall drilling stability and deviation control |

| Apparent Density | 2.6 – 2.8 g/cm³ | Typical for intrusive igneous rocks (granite, granodiorite); contributes to high UCS and abrasivity, requiring robust energy transfer via proper thread and hammer matching |

| Internal Friction Angle (φ) | 30° – 45° | Provides good stability under confined conditions; influences borehole wall integrity during drilling and reaming operations |

| Estimated Cohesion (c) | 1 – 5 MPa | Lower values in hydrothermally altered or weathered zones; higher cohesion supports better hole straightness but increases drilling resistance |

Drilling Performance Analysis

The experiment tracked the bit status at two critical milestones:

At 300m: The bit reached a significant depth while maintaining structural integrity.

- Final Performance (310m): The bit reached its functional limit at 310m.

Manufacturing Excellence & Material Science

RockHound tools are produced with a legacy of engineering expertise dating back to 1968.

Premium Materials: We use 45CrNiMo1V alloy steel and YK05 tungsten carbide grades for maximum durability.

High-Precision Machining: Thread accuracy is maintained within 0.02mm using advanced CNC equipment from Sandvik, Okuma, and DMG.

Advanced Button Insertion: We utilize a hot-pressing method with copper shims. The ductility of the copper provides a buffer, ensuring a perfect interference fit (±0.01mm) and better bonding with the hole wall.

Integrated Production: We are one of the few manufacturers with a full-process production line, including steel smelting, rolling, and forging.

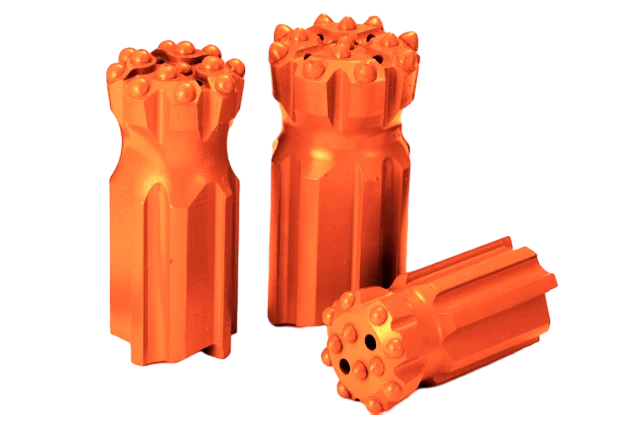

View RockHound R32 Retrac Button Bit

Premium Material: Forged from 45CrNiMo1V high-strength alloy steel for excellent fatigue resistance and impact toughness.

Superior Carbide Quality: Equipped with high-wear-resistance tungsten carbide buttons/inserts to maintain sharpness longer.

Optimized Flushing: Scientifically designed flushing holes ensure efficient debris removal and prevent over-heating.

Precision Threading: Standard R32 threads ensure a tight, reliable connection with the drill rod, reducing energy loss.

Versatile Designs: Available in Button, Cross, and X-type configurations to handle various geological conditions from fractured to solid rock.

- Wear Resistance: Special surface treatment processes (such as shot peening) significantly increase the hardness of the metal surface.