T38 MF Rod Description

RockHound T38 MF Rod (Male-Female) is engineered for maximum productivity in top hammer drilling applications. Unlike traditional extension rods, the MF design features an integrated female thread on one end, eliminating the need for separate coupling sleeves. This results in tighter connections, straighter holes, and significantly higher energy transmission from the rock drill to the bit.

Manufactured using ZK22CrNi3Mo high-strength alloy steel, these rods undergo advanced CNC machining and 20 hours specialized heat treatment to withstand the most abrasive rock conditions. Whether you are bench drilling or tunneling, our T38 MF rods deliver the reliability your project demands.

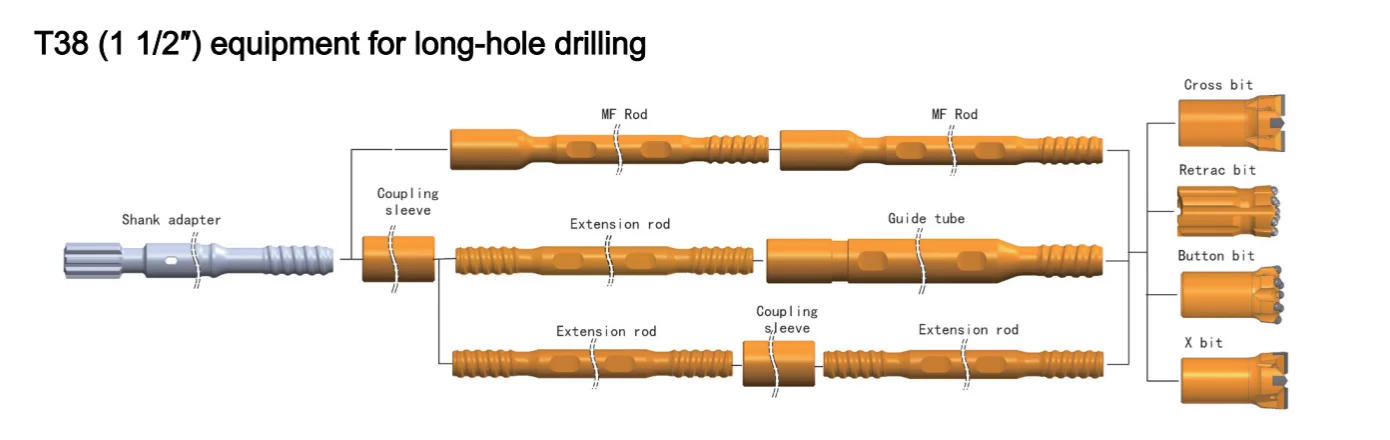

T38 MF Rod For Long-Hole Drilling

Key Features

Premium Material (ZK22CrNi3Mo): Utilizes high-grade nickel-chromium-molybdenum alloy steel, offering an ideal balance of toughness, hardness, and fatigue resistance.

Integrated MF Design: Reduces energy loss and thread wear by eliminating coupling sleeves, ensuring a more rigid drill string.

Precision T38 Threads: Expertly machined threads ensure easy uncoupling and long-lasting performance under high impact.

Enhanced Straightness: Optimized rod body diameter ($38\text{mm}$) provides better stability and minimizes hole deviation.

Carburized Finish: Advanced surface hardening treatment increases wear resistance and extends the service life of the rod.

Technical Specifications

| Part Number | Rod Type | Length (mm) | Length (ft) | Body Dia. (D) | Thread | Weight (kg) |

|---|---|---|---|---|---|---|

| 290-3809-7676 | T38-D38-T38 MF | 915 | 3′ | 38 mm (1 1/2″) | T38 | 8.3 |

| 290-3812-7676 | T38-D38-T38 MF | 1220 | 4′ | 38 mm (1 1/2″) | T38 | 10.9 |

| 290-3815-7676 | T38-D38-T38 MF | 1525 | 5′ | 38 mm (1 1/2″) | T38 | 13.3 |

| 290-3818-7676 | T38-D38-T38 MF | 1830 | 6′ | 38 mm (1 1/2″) | T38 | 15.8 |

Field Test Report: MF T38-R32 Drill Rods

Specification: ZK23CrNi3Mo H35×4305-T38/R32 (Hex 35mm, Length 4305mm)

Quantity: 8 Pieces

| Serial No. | Service Life / Footage (m) | Failure Mode |

|---|---|---|

| 1# | 3529 | Breakage at Small End Thread (Bit End) |

| 2# | 3753 | Breakage at Small End Thread (Bit End) |

| 3# | 3478 | Breakage at Small End Thread (Bit End) |

| 4# | 3389 | Breakage at Small End Thread (Bit End) |

| 5# | 3645 | Breakage at Small End Thread (Bit End) |

| 6# | 3725 | Breakage at Small End Thread (Bit End) |

| 7# | 3712 | Breakage at Small End Thread (Bit End) |

| 8# | 3549 | Breakage at Small End Thread (Bit End) |

| Average | 3597.5 m | Breakage at Small End Thread (Bit End) – 100% of samples |

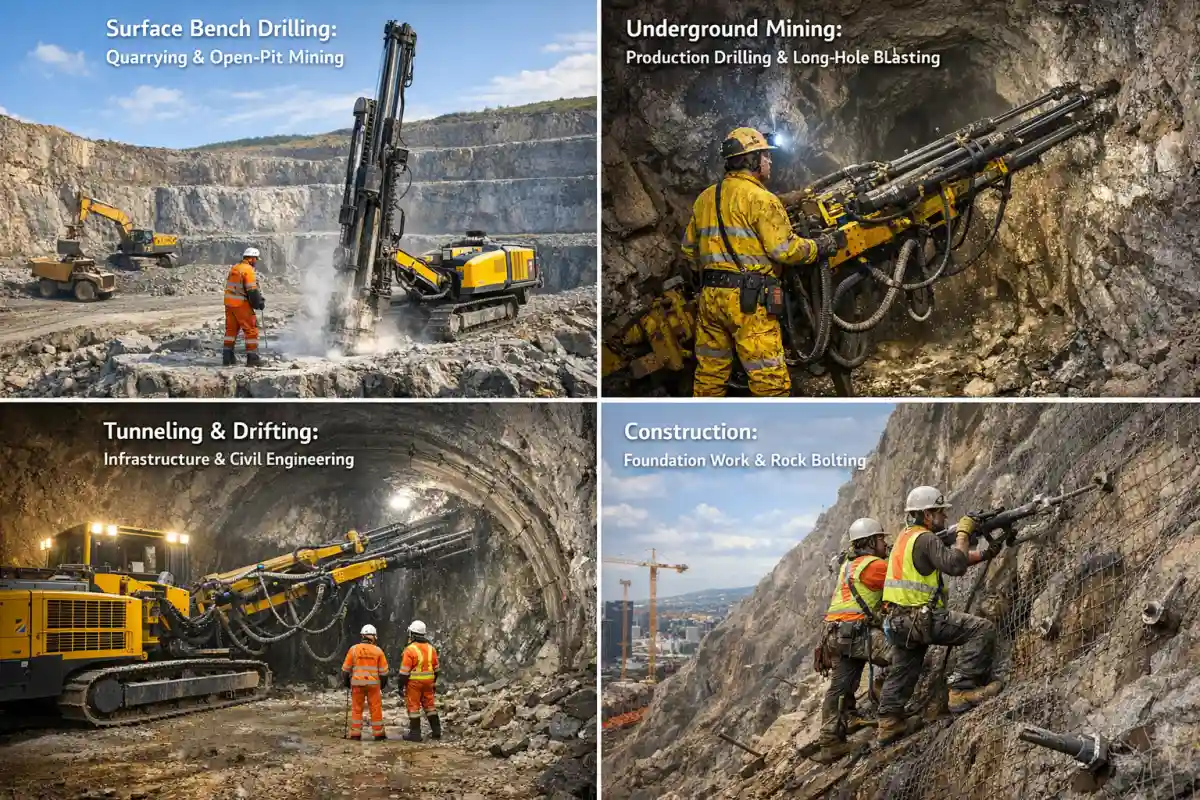

Applications

The T38 MF Rod is the industry standard for medium to hard rock formations, widely used in:

Surface Bench Drilling: Quarrying and open-pit mining.

Underground Mining: Production drilling and long-hole blasting.

Tunneling & Drifting: Infrastructure and civil engineering projects.

Construction: Foundation work and rock bolting.

Maintenance Tips for Longer Service Life

Thread Lubrication: Always apply high-quality thread grease to the male and female ends before connection to prevent galling.

Proper Break-in: Run new rods at lower impact pressure for the first few holes to “seat” the threads.

Check for Overheating: Ensure sufficient flushing (air/water) to prevent thermal cracks in the ZK22CrNi3Mo steel.

Straightness Inspection: Regularly check for rod bending; drilling with bent rods accelerates thread wear and increases the risk of breakage.

Avoid Over-torquing: Ensure the drill rig’s rotation torque is matched to the T38 thread specifications.

Related Production

FAQ

The T38 MF Rod features an integrated female thread (built-in coupling) on one end. This design eliminates the need for separate coupling sleeves, which leads to:

Straighter holes: A more rigid connection reduces bending.

Better energy transfer: Fewer joints mean more impact energy reaches the drill bit.

Easier handling: Faster rod changes and less inventory to manage (no extra couplings).

ZK22CrNi3Mo is a premium nickel-chromium-molybdenum alloy steel specifically chosen for high-stress drilling. Compared to standard steel, it offers:

Superior Fatigue Strength: Resists the constant vibration and impact of top hammer drifters.

Excellent Toughness: Prevents sudden snapping in hard or fractured rock formations.

Wear Resistance: Ensures the threads maintain their profile longer under high-friction conditions.

As shown in our technical specifications, we provide four standard lengths to suit different feed systems:

915mm (3ft)

1220mm (4ft)

1525mm (5ft)

1830mm (6ft)

All models maintain a standard 38mm body diameter for optimal stability.

Yes. RockHound T38 MF rods are manufactured to international standards. They are fully compatible with top hammer drilling rigs from major brands such as Epiroc (Atlas Copco), Sandvik, Furukawa, and Montabert that utilize T38 thread systems.

You should inspect the threads daily. Signs of critical wear include:

Thread "Rounding": The crests of the threads become sharp or significantly flattened.

Heat Discoloration: Darkening of the steel indicates excessive friction or lack of lubrication.

Loose Fit: If the connection feels wobbly even when tightened, the thread profile has likely eroded. Replacing worn rods early prevents damage to your shank adapters and bits.

Absolutely. While they are the "workhorse" for underground drifting and tunneling, their rigidity and high energy transmission also make them excellent for surface bench drilling in quarries where hole precision is critical.