In the world of top-hammer drilling, the Shank Adapter (also known as a striking bar) is the silent hero. Positioned at the very heart of the operation, it acts as the critical interface between the rock drill (drifter) and the drill string.

What is a Shank Adapter?

The shank adapter is designed to withstand the high-frequency impact energy of the drifter’s piston and transmit it efficiently into the drill rods and bits. Because it is the first component to receive the blow, it must possess extreme fatigue strength and dimensional precision.

Shank Adapter Structure & Function

How It Works

According to industry standards and field data, a shank adapter performs three vital tasks simultaneously:

Impact Energy Transmission: It receives thousands of blows per minute from the piston. Its primary job is to transfer this kinetic energy into the drill string with minimal loss.

Torque Transfer: Through its external splines, the shank adapter engages with the drifter’s rotation chuck, providing the necessary torque to rotate the drill bit against the rock face.

Flushing Media Injection: Most shank adapters feature a flushing hole or a water port. This allows high-pressure water or air to pass through the center of the tools to clear cuttings from the borehole, preventing the bit from jamming.

Common Types of Shank Adapters

Choosing the right configuration is essential for system compatibility:

Male Threaded: The most common type, used for high-stress applications like drifting and tunneling.

Female Threaded: Used in specific drilling scenarios where space is limited or specialized couplings are required.

Brand Compatibility: High-quality shanks are engineered to be 100% interchangeable with major brands, including Epiroc (Atlas Copco), Sandvik (Tamrock), Furukawa, Montabert, and Ingersoll Rand.

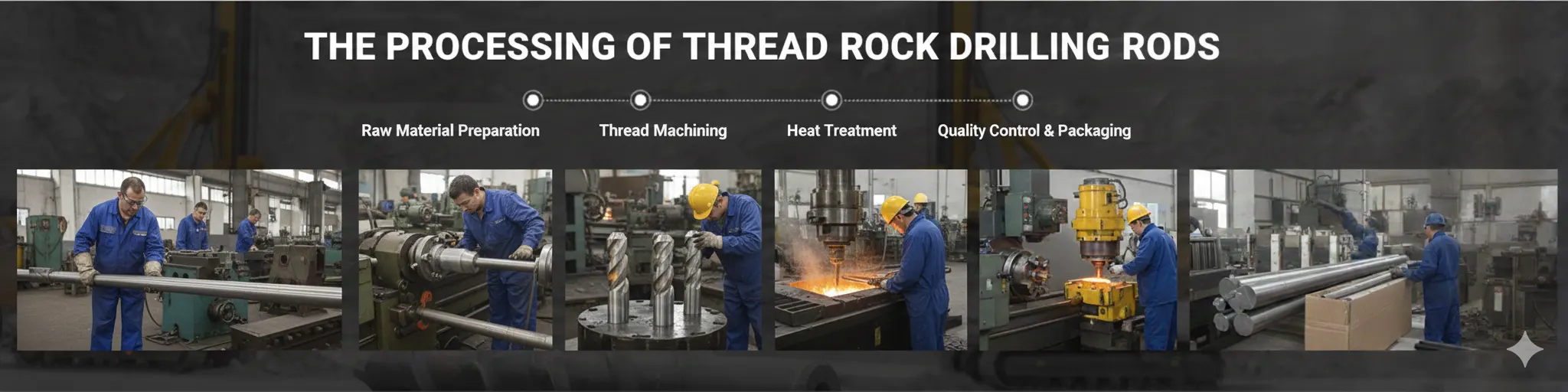

View Detail:Rock Drill Shank Adapter Production Process

How to Choose the Right Shank Adapter

Selecting the wrong shank can lead to catastrophic failure of the drifter’s internal parts. Consider these four factors:

Drifter Model:

Match the shank precisely to your rock drill model (e.g., COP 1838, HLX5, HD712).

Thread Connection:

Ensure the thread (R32, T38, T45, T51, GT60, etc.) matches your drill rods.

Material Quality:

Look for adapters made from high-strength ZK22CrNi3Mo alloy steel that has undergone carburization (surface hardening) to ensure a hard wear-resistant surface and a tough, shock-absorbing core.

Flushing Type:

Determine if you need internal or external flushing based on your rig’s configuration.

Maintenance & Troubleshooting

To achieve a service life of 10,000 to 20,000+ drill meters, follow these maintenance protocols:

Lubrication:

Ensure the rock drill’s oil-mist lubrication system is functioning. Dry splines lead to rapid friction wear and heat cracks.

Check for Straightness:

A bent shank adapter causes vibration and reduces the life of the drifter’s bushings and seals.

Monitor the Striking Face:

Inspect the end of the shank where the piston strikes. If you notice “mushrooming” (deformation) or pitting, replace it immediately. A damaged shank end will destroy your expensive drifter piston.

Thread Care:

Never force a connection. Use thread grease and ensure the coupling is tight. Loose connections cause “diesel effect” or thread burning.

Conclusion

Investing in a premium shank adapter is the most cost-effective way to lower your Cost Per Foot (CPF). By ensuring high energy transmission and protecting your drifter from damage, you maximize both productivity and tool longevity.

Need a specific shank adapter for your drifter? [Contact our technical team] for a compatibility check and a quick quote.

FAQ

The most common causes of failure include:

Lack of Lubrication: Insufficient oil-mist lubrication causes excessive friction and heat on the splines.

Misalignment: If the drifter is not perfectly aligned with the drill string, it creates bending stress.

Idle Blasting: Striking the shank when the bit is not in contact with the rock (blank firing) causes internal stress waves that lead to fatigue cracks.

Corrosion: Using acidic flushing water without proper post-operation maintenance can lead to stress corrosion pitting.

Under standard conditions, a high-quality shank adapter should last between 10,000 to 25,000 drill meters.

However, this varies significantly based on rock hardness (abrasiveness), drilling pressure, and how well the operator maintains the equipment.Regularly checking for "mushrooming" on the striking face is the best way to gauge replacement time.

Eros cubilia dui maecenas et facilisis at. Curae lacinia accumsan vulputate natoque ut luctus inceptos.

- Male Shank Adapters: These are the industry standard for most drifting, tunneling, and extension drilling applications where high bending stresses are present.

Female Shank Adapters: These are generally used when drilling space is very limited or when specific coupling requirements exist. Most modern hydraulic drifters prioritize male shanks for better energy transmission.

Yes, as long as the adapter is manufactured to OEM specifications.RockHound high-quality aftermarket shanks use the same premium 22CrNi3Mo alloy steel and carburization processes as original parts, offering a more cost-effective solution without sacrificing performance or risking damage to the drifter's piston.

You should replace the shank if you notice:

Mushrooming: The striking face is flattened or spreading outwards.

Spline Wear: The teeth (splines) are worn thin, leading to excessive play in rotation.

Thread Damage: The threads are stripped, "burned" (blue/black discoloration), or cracked.

Pitting: Deep corrosion or visible cracks on the main body of the shank.