Description

RockHound 7-degree Taper Chisel Bit is specifically engineered for small hole drilling in mining, quarrying, and tunneling. Crafted from premium ZK45CrNiMoV (45CrNiMoV) alloy steel, these bits offer exceptional fatigue strength and wear resistance. Combined with high-quality tungsten carbide inserts, our chisel bits ensure rapid penetration rates and long service life in various rock formations, particularly soft to medium-hard rock.

Features

High-Grade Material: Forged with ZK45CrNiMoV steel, providing superior toughness and preventing shank breakage.

Premium Carbide Inserts: Features wear-resistant carbide that maintains sharpness longer, reducing the frequency of regrinding.

Precision 7° Taper: Ensures a tight and secure connection with the taper drill rods, minimizing energy loss during impact.

Cost-Effective: The simple chisel design is easy to sharpen and highly economical for small-diameter drilling projects.

Optimized Flushing: Designed for efficient chip removal to prevent jamming and increase drilling speed.

Specifications

| Diameter (mm) | Diameter (inch) | Insert (H×T mm) | Taper | Product Code | Weight (kg) |

|---|---|---|---|---|---|

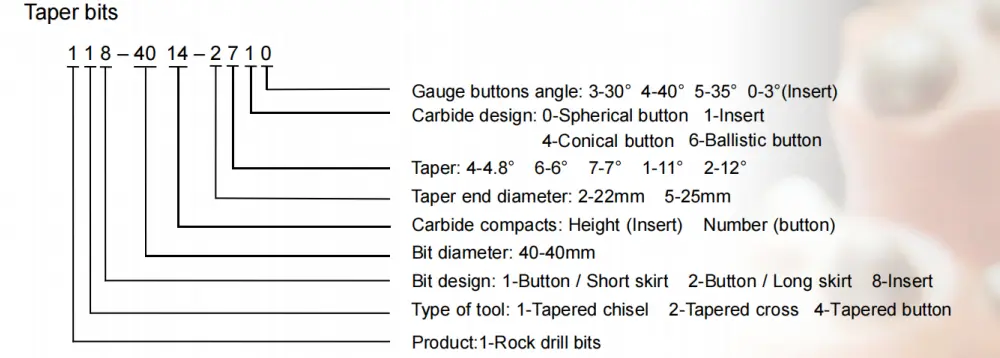

| 32 | 1 1/4″ | 13×8 / 15×8 | 7° | 118-3213/15-2710 | 0.2 |

| 34 | 1 11/32″ | 13×8 / 15×8 | 7° | 118-3413/15-2710 | 0.3 |

| 36 | 1 13/32″ | 13×8 / 15×8 | 7° | 118-3613/15-2710 | 0.3 |

| 38 | 1 1/2″ | 13×9 / 15×10 / 17×10 | 7° | 118-3813/15/17-2710 | 0.3-0.4 |

| 40 | 1 9/16″ | 13×9 / 15×10 / 17×10 | 7° | 118-4013/15/17-2710 | 0.3-0.4 |

| 42 | 1 5/8″ | 13×9 / 15×10 / 17×10 | 7° | 118-4213/15/17-2710 | 0.4-0.5 |

| 43 | 1 5/8″ | 13×9 / 15×10 / 17×10 | 7° | 118-4313/15/17-2710 | 0.4-0.5 |

Application

These taper chisel bits are widely used with handheld rock drills (like Y24, YT28) for:

- Mining: Small hole blasting in underground mines.

- Quarrying: Dimension stone industry (granite, marble) and aggregate production.

- Tunneling: Bolt hole drilling and short-hole excavation.

- Construction: Road maintenance, trenching, and foundation work.

Maintenance Tips

To maximize the lifespan of your ZK45CrNiMoV chisel bits:

Timely Grinding: Do not wait until the carbide is completely flat. Regrind when the “anti-taper” appears to prevent stress fractures.

Correct Installation: Ensure the taper bore of the bit and the taper of the rod are clean and match perfectly (7°).

Proper Flushing: Always use sufficient water or air pressure to clear cuttings and cool the bit head.

Avoid Overheating: If the bit becomes excessively hot, allow it to cool naturally. Never quench it in cold water, as this causes thermal cracking.

How to Choose the Right Bit

Choosing the right bit is crucial for maximizing your drilling efficiency and reducing the cost per meter. While Taper Chisel Bits are legendary for their simplicity, Taper Button Bits offer modern performance advantages.

Rock Hardness:

Chisel bits are best suited for soft to medium rock. For very hard or abrasive rock, consider switching to Taper Button Bits.

Hole Diameter:

Match the bit diameter to your explosive charge or bolt requirements.

Taper Angle:

Ensure the bit’s taper angle (e.g., 7°) exactly matches your drill rod’s taper to avoid premature failure of the connection.

| Feature | Taper Chisel Bit | Taper Button Bit |

|---|---|---|

| Design | Single wedge-shaped carbide blade | Multiple hemispherical or conical carbide “buttons” |

| Best Rock Type | Soft to Medium-Hard (e.g., Limestone, Sandstone) | Hard to Very Hard & Abrasive (e.g., Granite, Basalt, Quartzite) |

| Drilling Speed | Very fast in soft rock; slows significantly in hard rock | Consistent high penetration rates across various rock types |

| Hole Straightness | Prone to deviation in fractured / broken ground | Excellent stability; straighter, cleaner holes |

| Flushing Efficiency | Moderate to poor: Larger, flatter cuttings can clog in fractured rock; more regrinding of debris | Superior: Smaller, uniform cuttings + better exposure of flushing paths → faster cuttings removal, less clogging, cooler bit operation |

| Maintenance | High: Frequent regrinding required to maintain sharp edge | Low to maintenance-free; much less frequent grinding needed |

| Initial Cost | Lower: Economical for small-scale or budget projects | Higher upfront but longer service life & lower cost per meter |

| Risk of Jamming | Higher risk in fissured or broken rock | Lower risk due to multiple contact points & better flushing |

FAQ

The taper angle must match your drill rod exactly. 7-degree tapers are the industry standard for lightweight, handheld rock drills (like the YT24 or Y26) used in small-hole drilling. If you are unsure, measure the taper length and diameter of your rod, or check the markings on your current equipment. Using mismatched angles will lead to bit loss or rod damage.

Taper Chisel Bits are your best choice for soft to medium-hard rock and projects with a tight budget. They are easier to regrind and more economical. However, if you are drilling into very hard or abrasive rock (like granite), we recommend our Taper Button Bits for higher efficiency and straighter holes.

To maintain optimal penetration rates, you should regrind the tungsten carbide insert once the "wear flat" on the cutting edge reaches 3mm in width. Continuing to drill with a blunt bit increases the stress on the ZK45CrNiMoV body and can lead to carbide fracturing.

Yes. RockHound 7° taper chisel bits are designed with optimized flushing holes that support both air-cooled and water-cooled drilling. This ensures efficient chip removal and prevents the bit from overheating and jamming.

Carbide loss is often caused by excessive heat or improper taper fit.

Always ensure the bit is seated tightly on the rod.

Never "dry drill" without flushing.

Avoid over-grinding the steel around the carbide, as this weakens the support structure.