T51 Thread Button Bits Description

RockHound T51 Thread Retrac Button Bits are engineered to deliver maximum penetration rates and exceptional service life in the most demanding rock conditions. Featuring a specialized retrac skirt design, these bits are specifically optimized for fractured or loose formations where drill string retrieval can be challenging.

Manufactured from premium-grade tungsten carbide and high-strength alloy steel, our T51 bits ensure superior wear resistance and hole straightness. Whether you are engaged in open-pit mining or underground tunneling, these bits provide the reliability needed to minimize downtime and reduce your cost per meter drilled.

Features

- Superior Retrac Skirt Design: The tapered “retrac” body allows for easier retrieval of the drill string, significantly reducing the risk of stuck tools in broken rock or caving ground.

- Premium Tungsten Carbide Inserts: Equipped with high-quality ballistic or spherical buttons that offer high impact toughness and excellent abrasion resistance.

- Enhanced Flushing Channels: Optimized water/air holes ensure efficient cuttings removal, preventing regrinding and cooling the bit head effectively.

- High-Strength Steel Body: Heat-treated alloy steel body provides maximum fatigue strength to withstand the high-frequency impacts of modern hydraulic hammer drills.

- Precise T51 Thread Connection: Fully compatible with standard T51 drill rods and extension steels, ensuring a tight energy transfer and easy decoupling.

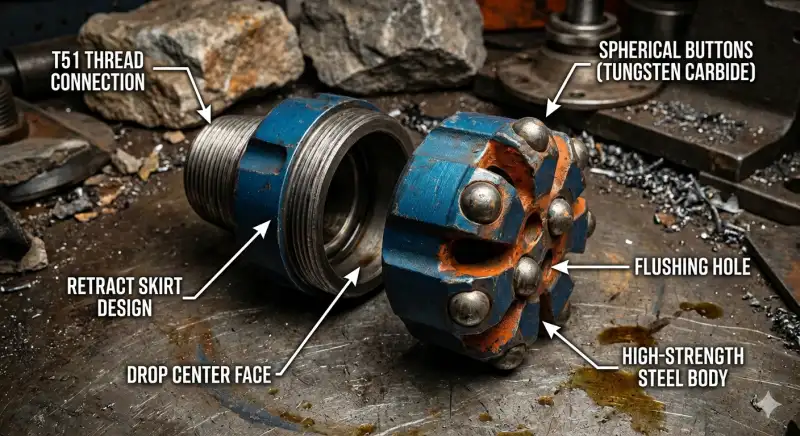

T51 Thread Retrac Button Bit Structure Diagram

1. T51 Thread Connection

This is the interface connecting the drill bit and the drill rod. T51 is a standard high-strength thread specification, commonly found in high-power hydraulic rock drills.

Function: Ensures efficient transmission of high-frequency impact energy to the drill bit face, while also providing good fatigue resistance and facilitating quick decoupling after drilling is complete.

2. Retrac Skirt Design

The drill bit body features a distinct inverted conical or longitudinal groove design.

Function: The core design to prevent stuck drill bit. When drilling in fractured rock formations, rock debris can easily fall and jam the drill bit. The retraction skirt has a “back-cutting” effect when withdrawing the drill string, clearing away fallen debris behind it and ensuring smooth drill string retraction, greatly reducing the risk of lost drill bit.

3. Spherical Buttons (Tungsten Carbide)

The rounded part, embedded at the top of the drill bit, is made of tungsten carbide.

Function: The core component for breaking rock. The hemispherical teeth are extremely strong and durable, with high impact resistance. They pulverize rock through high-frequency impacts, making them the preferred tooth type for handling extremely hard rock, and they wear out more slowly than pointed teeth.

4. Drop Center Face

The center plane of the drill bit is concave inward.

Function: Excellent guidance. This structure stabilizes the drill bit during drilling, similar to a center drill, preventing hole deviation in hard or jointed rocks and ensuring hole straightness.

5. Flushing Hole

A circular through-hole located on the drill bit end face.

Function: During drilling, water or compressed air is ejected from the hole, blowing the cuttings generated from the breakage from the bottom of the hole to the surface. It also serves to cool the drill bit, preventing the alloy teeth from overheating and breaking or falling off.

6. High-Strength Steel Body

The drill bit body, typically made of alloy steel that has undergone special heat treatment.

Function: It is the carrier of all components. High-quality steel must possess extremely high fatigue strength to withstand thousands of high-energy impacts per minute from the rock drill without fracture or deformation.

Specifiation

| Thread bit, Button | D (Diameter) | Buttons (No × Size mm) | Gauge Button Angle | Thread | Product Code | Weight (kg) | ||

|---|---|---|---|---|---|---|---|---|

| mm | inch | Gauge | Centre | |||||

| Button (Standard) |

89 | 3 1/2 | 9 × 11 | 6 × 10 | 35° | T51 | 173-8915-7805 | 4.0 |

| Button | 102 | 4 | 9 × 12 | 6 × 12 | 35° | T51 | 173-0215-7805 | 4.8 |

| Button | 115 | 4 1/2 | 9 × 13 | 6 × 12 | 35° | T51 | 173-1515-7805 | 5.8 |

| Button | 127 | 5 | 9 × 14 | 6 × 13 | 35° | T51 | 173-2715-7805 | 8.0 |

| Button / Drop Center | 89 | 3 1/2 | 8 × 12 | 6 × 11 | 35° | T51 | 175-8914-7805 | 4.8 |

| Button / Flat / Retrac | 89 | 3 1/2 | 9 × 11 | 6 × 10 | 35° | T51 | 174-8915-7805 | 4.9 |

| Button / Flat / Retrac | 102 | 4 | 9 × 12 | 6 × 12 | 35° | T51 | 174-0215-7805 | 7.1 |

| Button / Drop Center / Retrac | 89 | 3 1/2 | 8 × 12 | 6 × 11 | 35° | T51 | 176-8914-7805 | 4.7 |

| Button / Drop Center / Retrac | 89 | 3 1/2 | 8 × 12 | 7 × 11 | 40° | T51 | 176-8915-7864 | 4.7 |

| Button / Drop Center / Retrac | 102 | 4 | 8 × 12 | 7 × 12 | 40° | T51 | 176-0215-7864 | 5.3 |

RockHound T51 retrac bits feature heavy-duty skirts and standard/large clearance designs to ensure optimal flushing and easy retrieval in sticky or fractured rock formations.

Button Shape Comparison

| Button Type | Features | Performance | Application Suggestions |

|---|---|---|---|

| Spherical Button | Rounded, arc-shaped top; very thick and robust design. | Exceptional durability. While penetration speed is slightly slower, it is extremely resistant to fracturing. | Ideal for extremely hard rock formations or high-impact drilling environments. |

| Ballistic Button | Pointed, streamlined top design. | High Rate of Penetration (ROP). Cuts deeper into rock with 10-20% higher efficiency than spherical buttons. | Best for soft to medium-hard rock, ideal for projects prioritizing rapid construction progress. |

| Parabolic Button | A balanced hybrid design between spherical and ballistic shapes. | Combines the high speed of ballistic buttons with the long service life of spherical buttons. | The best-selling universal model for independent sites, offering an excellent cost-performance ratio. |

Applications

The T51 Retrac Button Bit is a versatile tool designed for heavy-duty top hammer drilling in various industries:

- Bench Drilling: Ideal for production drilling in medium to hard rock formations in quarries and open-pit mines.

- Long-Hole Drilling: Ensures hole straightness and efficient energy transfer for deep hole underground mining.

- Tunneling & Drifting: Provides the durability required for face drilling and bolting in civil engineering projects.

- Construction: Used for foundation work, anchoring, and site preparation where complex geological conditions exist.

How does T51 Thread Button Bits WorK?

Related Products

T51 Extension Rods (4000mm / 4600mm)

T51 Shank Adapter (Compatible with Atlas Copco, Sandvik, Furukawa)

Coupling Sleeves T51

FAQ

Spherical (Round): Use for extremely hard rock (e.g., Quartzite, Granite). They offer the longest life and highest resistance to fracture.

Ballistic (Pointed): Use for soft to medium-hard rock. They provide a significantly higher Penetration Rate (ROP) but wear down faster in abrasive ground.

This is often caused by overheating or excessive feed pressure. Ensure that your flushing (water or air) is at the correct pressure to clear cuttings instantly. Also, avoid "collaring" the hole with maximum impact power; start with lower settings until the bit is fully engaged in the rock.

Do not wait for the buttons to become completely flat. We recommend regrinding when:

The penetration rate drops by 15-20%.

The "anti-wear" flat on the button reaches 1/3 of the button diameter. Regular sharpening extends the total life of the bit and protects the drill rig from excessive vibration.

Yes. RockHound T51 bits are manufactured to global industry standards. They are fully compatible with Atlas Copco (Epiroc), Sandvik, Furukawa, Montabert, and other major top-hammer hydraulic drifters using T51 extension rods.

We use premium grade Tungsten Carbide inserts from industry-leading suppliers and high-fatigue-strength alloy steel for the bit body. Each bit undergoes specialized heat treatment to ensure the perfect balance between hardness and toughness.