With a legacy dating back to 1968, our engineering team possesses deep-rooted expertise in rock drilling metallurgy. We don't just make tools; we understand the "DNA" of the steel required for the toughest terrains.

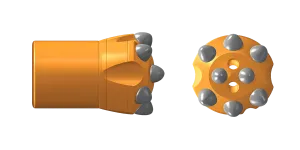

Unlike standard cold-pressing, our hot-fitting process with copper shims ensures a 100% snug fit between the carbide and the bit body. This significantly reduces the risk of button failure and enhances durability in high-impact environments.

We are the only manufacturer in the region with a complete production chain—from raw steel smelting to final forging. This allows us to control material purity and quality at every single stage, ensuring unparalleled product consistency.

Utilizing world-class CNC machinery from Okuma and DMG, we achieve thread tolerances of 0.02mm and insert fits of ±0.01mm. This precision translates to higher energy transfer efficiency and longer service life for your drill string.

Our factory is equipped with over 360 sets of advanced industrial machines, including 5-axis machining centers and automated straightening machines. This high-tier infrastructure guarantees that every RockHound tool meets international OEM standards.

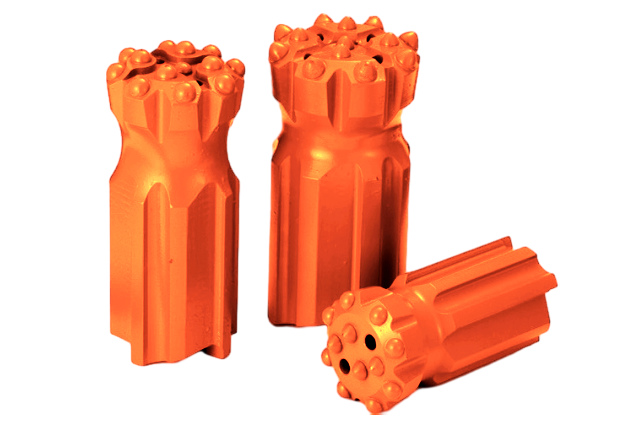

Button Bit Body: 45CrNiMo1V (Alloy Grade: YK05).

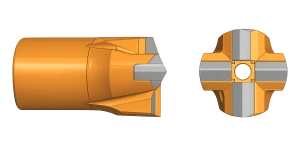

Tapered Bits: 45CrNiMoVa, 42CrMo, 35CrMo.

| Product | Specs | Material | Result |

|---|---|---|---|

| Drifting Rod | H25×2000-R25 | ZK22CrNi3Mo | QUALIFIED |

C:0.22 | Si:0.30 | Mn:0.73 | Cr:1.34 | Mo:0.25 | Ni:3.05

Remove decarburized layer, rough machining of outer diameter, calibrate head cutting angle.

Eliminate oxidation. Base hardness reaches HRC 45-50 to improve fatigue strength.

Eliminate internal stresses, improve toughness, and prevent fracture under heavy-load impact.

Hot-setting combined with copper brazing sheets to absorb shock. Match precision within 0.01mm.

| Rock Type | Angle | Logic |

|---|---|---|

| Extremely Hard | 38°–42° | Prevents chipping |

| Medium Hard | 35° | Optimal balance |

| Soft/Abrasive | 30°–33° | Aggressive ROP |

Utilizes high-strength steel shot to impact the surface, removing oxide scale and generating compressive stress.

Result:Significantly improved fatigue life and surface preparation for coating.

Environmentally friendly electrostatic spraying (Blue, Orange, Black).

VOC emissions meet standards; excellent anti-adhesion properties for field work.

Thickened custom boxes (5-10 pcs) + Export-grade fumigated wooden crates.

Laser traceability codes (100mm*100mm) for project management.

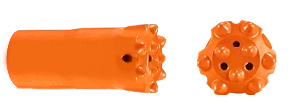

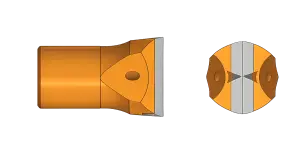

In top hammer drilling, the rock drill generates high-frequency impact energy. This energy travels through the drill rod and reaches the top hammer button bit(typically 2,000–5,000 blows/min,200–500 joules per blow).

When the impact reaches the bit, the tungsten carbide buttons strike the rock surface, creating cracks and fractures. These buttons are specifically designed to withstand high impact and abrasion.

At the same time, the drill string rotates, allowing the button bit to hit fresh rock surfaces continuously. This rotation ensures(usually 50–150 rpm, the bit rotates ~5–15° per blow).

Air or water flows through the flushing holes to remove rock cuttings, cool the bit, and prevent bit jamming. Proper flushing is critical for top hammer drilling performance.