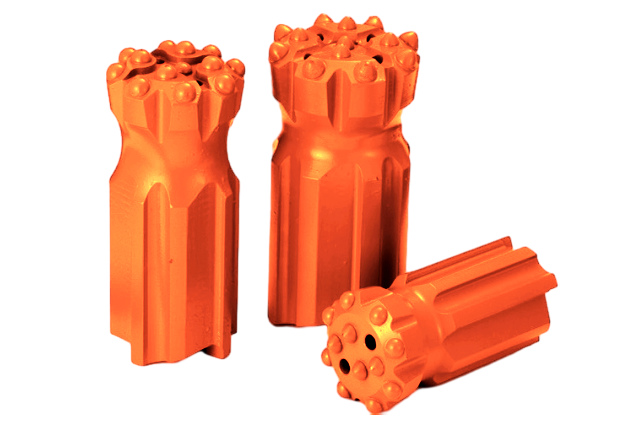

Manufactured with high-grade 22CrNi3Mo steel to withstand extreme impact and rotation torque.

Advanced 20-hours heat treatment ensures a wear-resistant surface and a tough core to prevent fractures.

RockHound tools are produced with a legacy of engineering expertise dating back to 1968.

Perfect fit with Atlas Copco, Sandvik, and other major brands to prevent “loose joints” and energy loss.

Field-tested to last 15-20% longer than standard aftermarket alternatives.

Efficient Energy Transfer: It ensures that the high-frequency impact energy from the rock drill’s piston is transmitted through the drill string to the bit with minimal loss.

Precision Alignment: It maintains the axial alignment of the drill string, preventing hole deviation and reducing bending stress on the threads.

Stress Distribution: High-quality sleeves are designed to dissipate the intense shock waves, preventing premature thread stripping or “fretting.”