Manufactured from elite-grade ZK22CrNi3Mo alloy steel to ensure maximum fatigue resistance and structural integrity under high-frequency impacts.

RockHounde mature carburization process creates a diamond-hard wear-resistant surface while maintaining a tough, shock-absorbing core to prevent premature snapping.

Engineered to provide a flat, precise striking face that ensures 100% impact energy transfer, significantly increasing your penetration rate and reducing "Cost Per Meter."

Every shank is crafted with high-precision CNC technology to guarantee a perfect fit for splines and threads, minimizing vibration and protecting your drifter’s internal components.

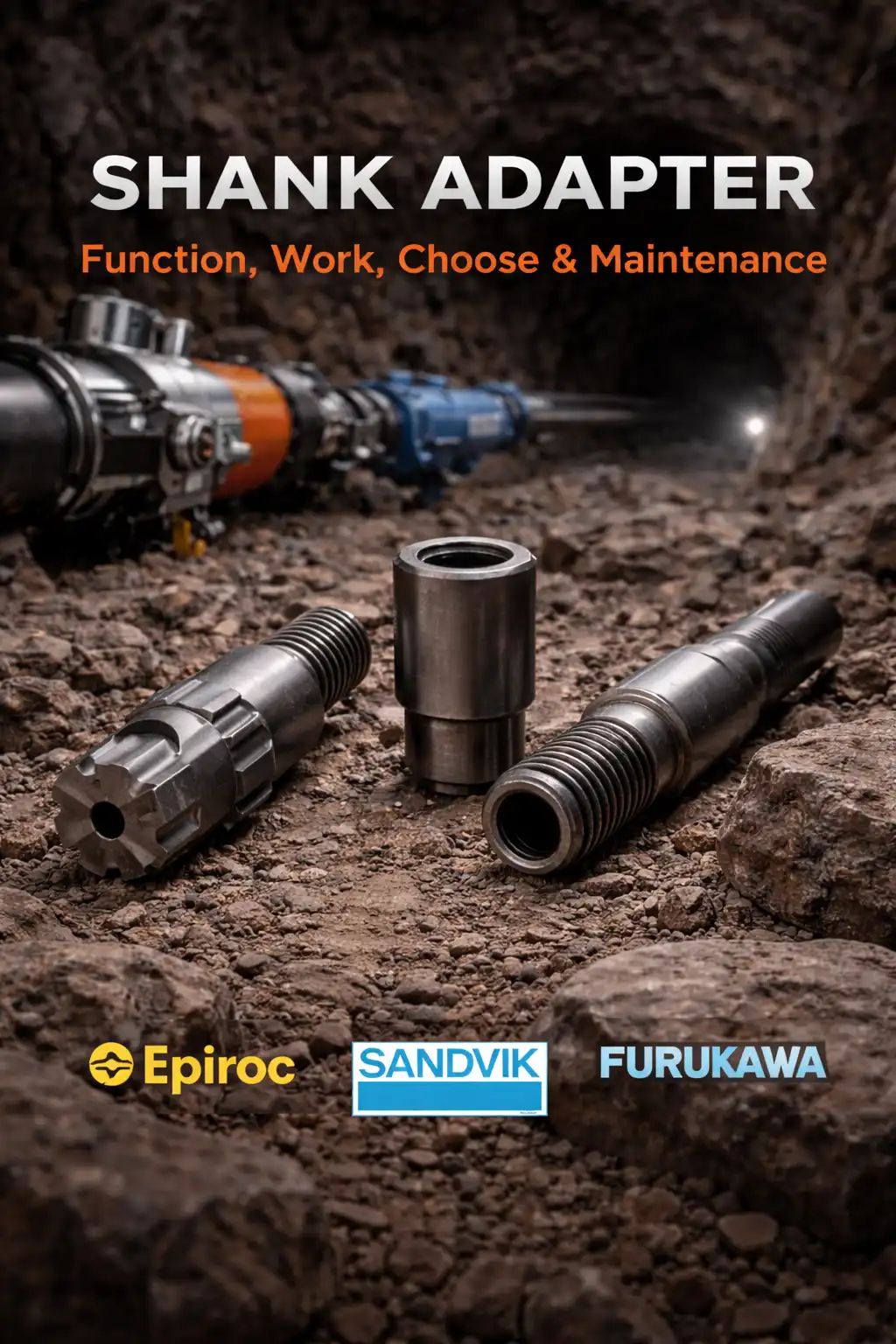

Fully interchangeable with major global brands including Epiroc (Atlas Copco), Sandvik, Furukawa, and Montabert, ensuring seamless integration with your existing fleet.

According to industry standards and field data, a shank adapter performs three vital tasks simultaneously:

Impact Energy Transmission:It receives thousands of blows per minute from the piston. Its primary job is to transfer this kinetic energy into the drill string with minimal loss.

Torque Transfer:Through its external splines, the shank adapter engages with the drifter’s rotation chuck, providing the necessary torque to rotate the drill bit against the rock face.

Flushing Media Injection: Most shank adapters feature a flushing hole or a water port. This allows high-pressure water or air to pass through the center of the tools to clear cuttings from the borehole, preventing the bit from jamming.