Product Description

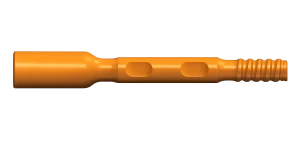

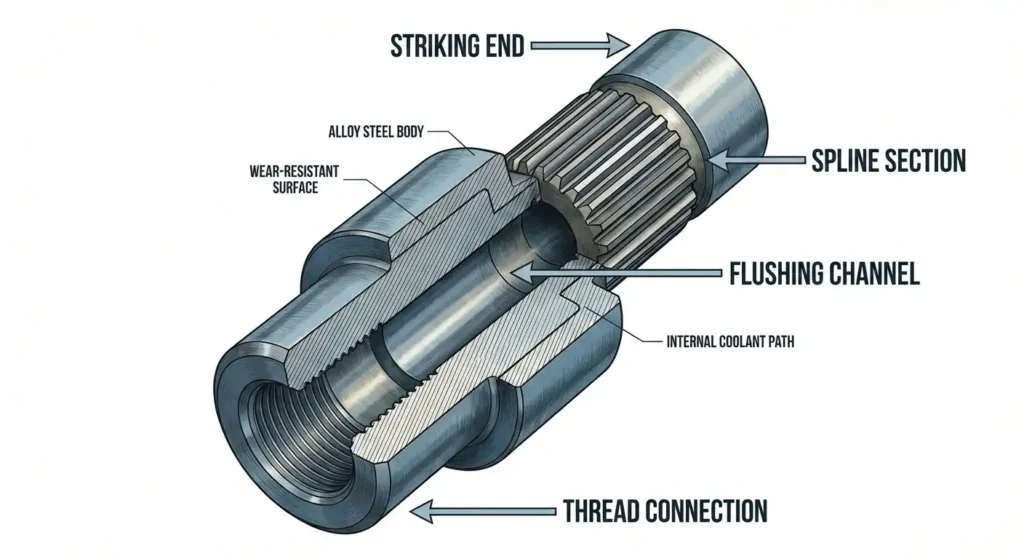

The Cop 1032 HL Shank Adapter is a critical component designed to transmit high-impact energy from the hydraulic drifter to the drill string. Engineered for high-frequency rock drilling, our shank adapters are fully compatible with Atlas Copco (Epiroc) COP series hydraulic drifters.

By utilizing premium ZK22CrNi3Mo alloy steel and advanced CNC machining, we ensure that every shank adapter offers superior fatigue strength and service life, even in the most demanding geological conditions.

Material: ZK22CrNi3Mo

The choice of material is what sets our products apart. We use ZK22CrNi3Mo, a high-strength alloy steel specifically formulated for impact tools:

Superior Toughness:

High resistance to impact energy to prevent premature fracturing.

Carburizing Heat Treatment:

Enhances surface hardness to HRC 58-62 while maintaining a flexible core.

Fatigue Resistance:

Specifically optimized to withstand millions of high-frequency stress cycles.

Structure & Features

Precision CNC Machining:

Ensures 100% compatibility with the internal splines of the Cop 1032 HL drifter.

Optimized Thread Design:

Available in R32 and T38 to match your existing drill rods.

High Energy Transfer:

Designed to minimize energy loss, increasing your ROP (Rate of Penetration).

Corrosion Resistance:

Specially treated surface to withstand harsh underground environments.

Specifications

| Drifter Model | Thread | Length (L) | Diameter (D) | Product Code | Weight (kg) |

|---|---|---|---|---|---|

| Cop 1032 HL | R32 | 510 mm | 45 mm | 418-4551-5154 | 4.7 |

| Cop 1032 HL | T38 | 510 mm | 45 mm | 418-4551-5176 | 5.0 |

Applications

RockHound’s Cop 1032 HL shank adapters are widely used in various heavy-duty drilling operations:

Underground Mining: Production drilling and drifting.

Tunneling: Face drilling and bolting.

Quarrying: Bench drilling and secondary blasting.

Civil Engineering: Foundation work and slope stabilization.

Maintenance Tips for Longer Service Life

Proper Lubrication: Always ensure the drifter’s lubrication system is functioning to reduce friction on the splines.

Thread Protection: Use high-quality thread grease to prevent galling and ease uncoupling.

Regular Inspection: Check for signs of fatigue or thread wear. Replace the shank adapter if the threads are worn by more than 25%.

Straight Alignment: Ensure the drill rig is perfectly aligned with the hole to reduce bending stress on the shank.

Related Production

FAQ

Yes. Atlas Copco Cop 1032 HL shank adapters are manufactured according to strict OEM standards. They are 100% interchangeable with Atlas Copco (Epiroc) part numbers 418-4551-5154 (R32) and 418-4551-5176 (T38), ensuring a perfect fit for your hydraulic drifters.

ZK22CrNi3Mo is a premium high-strength alloy steel that offers a superior balance of hardness and toughness. Unlike standard steel, it undergoes advanced carburizing heat treatment, providing a wear-resistant surface (HRC 58-62) and a flexible core. This significantly reduces the risk of shank breakage and extends service life by 20-30% in hard rock conditions.

The choice depends on your specific drilling requirements:

R32 threads are typically used for smaller hole diameters and lighter drilling tasks, offering easy uncoupling.

T38 threads are designed for larger holes and higher impact energy, providing a more rigid connection and better power transmission. Please check your current drill rod (extension rod) thread before ordering.

Every shank adapter undergoes precision CNC machining and rigorous spline gauging. We ensure that the dimensions (510mm length, 45mm diameter) and the internal/external spline tolerances match the drifter’s drive bush perfectly, minimizing vibration and protecting your drifter’s internal components.

We recommend storing them in a dry, ventilated area. Each adapter is shipped with an anti-rust coating, but for long-term storage, applying a thin layer of industrial oil and keeping them off the ground (on pallets) is recommended to prevent surface corrosion.