T38 Extension Rod Description

RockHound T38 Extension Rods are engineered to deliver maximum impact energy and durability in demanding top hammer drilling environments. Manufactured using premium ZK22CrNi3Mo alloy steel, these rods are designed to handle the high-stress conditions of modern hydraulic rock drills.

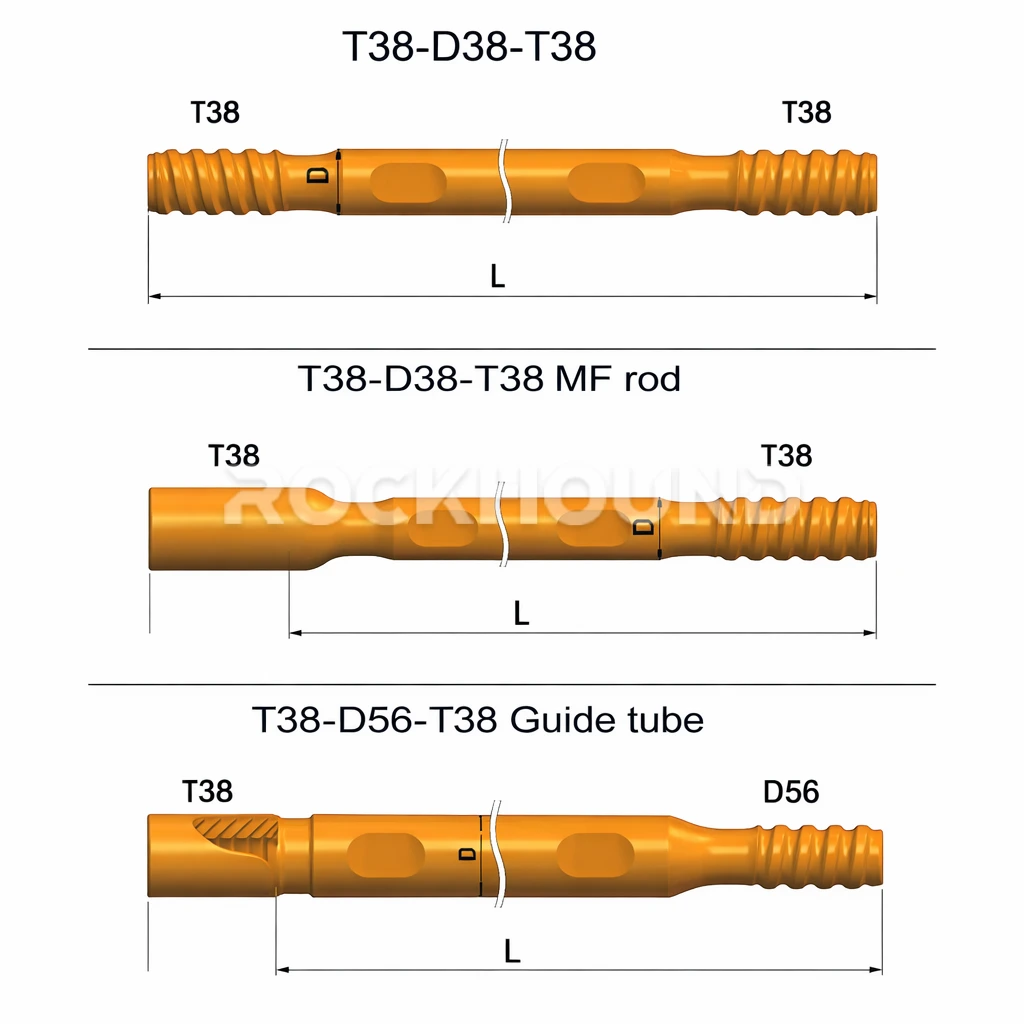

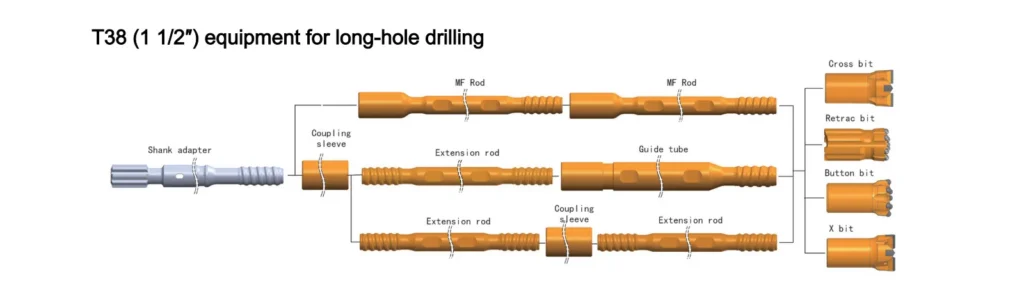

Whether you need standard T38-D38-T38 extension rods, MF (Male/Female) rods for faster coupling, or T38 guide tubes for improved hole straightness, our products ensure reduced downtime and lower drilling costs per meter.

Material & Features

Raw Material:ZK22CrNi3Mo

RockHound utilize ZK22CrNi3Mo, a high-strength chrome-nickel-molybdenum alloy steel, specifically chosen for its excellent hardenability and toughness. Through advanced 20 hours carburization heat treatment, the rod surface achieves superior wear resistance while maintaining a flexible core to resist fatigue-induced breakage.

Key Features:

High Fatigue Strength: The ZK22CrNi3Mo alloy significantly extends the service life in high-frequency impact applications.

Precision T38 Threads: CNC-machined threads ensure a perfect fit with shank adapters and bits, preventing energy loss and thread galling.

Optimal Straightness: Advanced manufacturing processes guarantee rod straightness, reducing hole deviation and stress on the drill string.

Diverse Configurations: Available in standard extension rods, Speed (MF) rods, and Guide tubes to meet various geological conditions.

Specifications

| Product Type | Model | Length (mm) | Length (foot) | Diameter (mm) | Diameter (inch) | Product Code | Weight (kg) |

|---|---|---|---|---|---|---|---|

| Extension Rod | T38-D38-T38 | 1220 | 4 | 38 | 1 ½ | 280-3812-7676 | 10.0 |

| Extension Rod | T38-D38-T38 | 1525 | 5 | 38 | 1 ½ | 280-3815-7676 | 12.4 |

| Extension Rod | T38-D38-T38 | 1830 | 6 | 38 | 1 ½ | 280-3818-7676 | 14.9 |

| MF Rod | T38-D38-T38 | 915 | 3 | 38 | 1 ½ | 290-3809-7676 | 8.3 |

| MF Rod | T38-D38-T38 | 1220 | 4 | 38 | 1 ½ | 290-3812-7676 | 10.9 |

| MF Rod | T38-D38-T38 | 1525 | 5 | 38 | 1 ½ | 290-3815-7676 | 13.3 |

| MF Rod | T38-D38-T38 | 1830 | 6 | 38 | 1 ½ | 290-3818-7676 | 15.8 |

| Guide Tube | T38-D56-T38 | 1220 | 4 | 56 | 2 ⅛ | 200-5612-7676 | 12.6 |

| Guide Tube | T38-D56-T38 | 1525 | 5 | 56 | 2 ⅛ | 200-5615-7676 | 14.0 |

| Guide Tube | T38-D56-T38 | 1830 | 6 | 56 | 2 ⅛ | 200-5618-7676 | 17.4 |

Field Test Report: MF T38-R32 Drill Rods

Specification: ZK23CrNi3Mo H35×4305-T38/R32 (Hex 35mm, Length 4305mm)

Quantity: 8 Pieces

| Serial No. | Service Life / Footage (m) | Failure Mode |

|---|---|---|

| 1# | 3529 | Breakage at Small End Thread (Bit End) |

| 2# | 3753 | Breakage at Small End Thread (Bit End) |

| 3# | 3478 | Breakage at Small End Thread (Bit End) |

| 4# | 3389 | Breakage at Small End Thread (Bit End) |

| 5# | 3645 | Breakage at Small End Thread (Bit End) |

| 6# | 3725 | Breakage at Small End Thread (Bit End) |

| 7# | 3712 | Breakage at Small End Thread (Bit End) |

| 8# | 3549 | Breakage at Small End Thread (Bit End) |

| Average | 3597.5 m | Breakage at Small End Thread (Bit End) – 100% of samples |

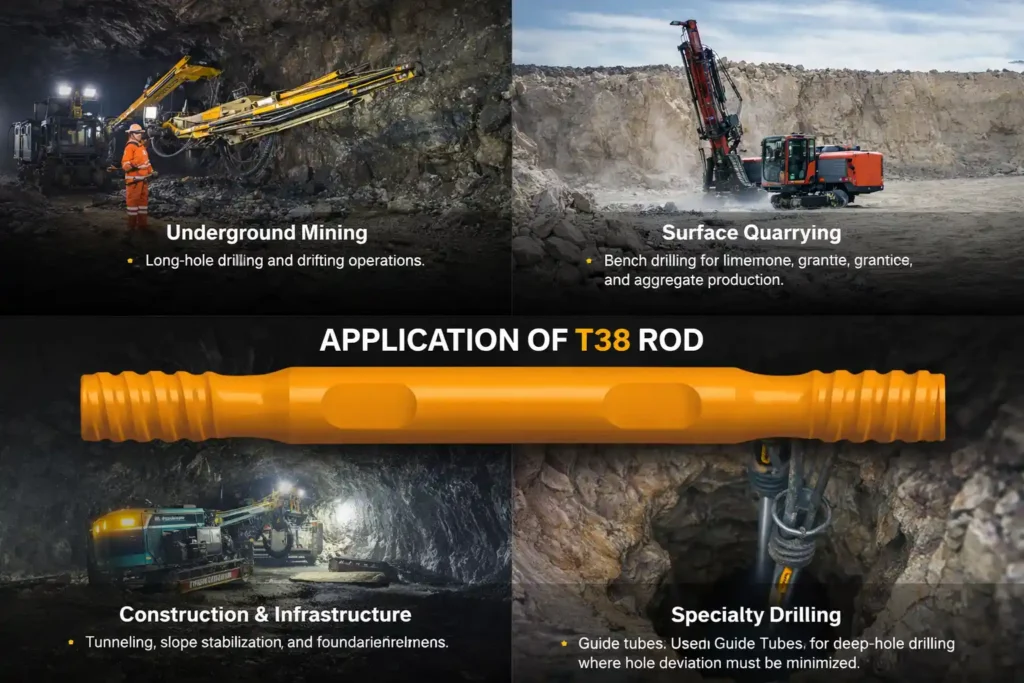

Applications

RockHound T38 drilling tools are compatible with world-leading rock drill rigs (e.g., Epiroc, Sandvik, Montabert) and are ideal for:

Underground Mining: Long-hole drilling and drifting operations.

Surface Quarrying: Bench drilling for limestone, granite, and aggregate production.

Construction & Infrastructure: Tunneling, slope stabilization, and foundation reinforcement.

Specialty Drilling: Using Guide Tubes for deep-hole drilling where hole deviation must be minimized.

Interchange OEM

T38 rods are high-quality alternatives to the following OEM series:

| OEM Brand | T38 Extension Rod Equivalent | T38 MF (Speed) Rod Equivalent |

|---|---|---|

| Sandvik | 7324-47xx-20 Series | 7324-15xx-20 Series |

| Epiroc | 905103xx Series | 905101xx Series |

| Mitsubishi | T38 Extension Series | T38 MF Series |

How To Maintenance T38 Extension Rod

Proper maintenance can increase your T38 rod’s lifespan by up to 30%:

Thread Lubrication: Always apply high-quality thread grease before connection to prevent cold welding and ease uncoupling.

Proper Tightness: Ensure the drill string is properly tightened; loose joints cause excessive thread wear and heat damage.

Rotation Management: Avoid “dry firing” or idling the drill without contact, as this creates excessive vibration that leads to fatigue cracks.

Regular Inspection: Check for signs of thread deformation or cracks on the rod body. Replace components that have reached their wear limits to avoid in-hole breakage.

Storage: Store rods in a dry place or apply anti-rust oil if they will be unused for long periods.

Related Production

FAQ About T38 Drilling Rods

ZK22CrNi3Mo is a premium high-strength alloy steel specifically designed for rock drilling. It offers a superior balance of toughness and fatigue strength. Combined with our carburization heat treatment, it provides a hard, wear-resistant surface while maintaining a flexible core to prevent brittle fractures during high-impact top hammer drilling.

Yes. Our T38 Extension Rods and MF (Speed) Rods are manufactured to industry-standard dimensions. They are 100% interchangeable with major brands like Epiroc (Atlas Copco), Sandvik, Furukawa, and Montabert. You can use our rods directly with your existing T38 shank adapters and bits.

- Extension Rods (Male-Male): Require a separate coupling sleeve to connect two rods. They are the traditional choice for various bench drilling tasks.

MF Rods (Speed Rods): Feature a male thread on one end and a female thread integrated into the other. This design eliminates the need for coupling sleeves, ensuring tighter connections, better energy transmission, and faster rod changes.

T38 Guide Tubes (such as the T38-D56-T38) have a larger diameter (56mm) compared to standard rods (38mm). They provide much higher rigidity, which is essential for maintaining hole straightness and reducing hole deviation in deep-hole drilling or complex geological formations.

Based on our standard production line, RockHound offer several lengths to match your drilling depth requirements:

Extension Rods: 1220mm (4'), 1525mm (5'), and 1830mm (6').

MF Rods: Available from 915mm (3') up to 1830mm (6').

Guide Tubes: Typically provided in 1220mm, 1525mm, and 1830mm lengths. (Custom lengths can be manufactured upon request to suit specific project needs.)

To prevent premature wear or "thread galling":

Always use thread grease: Apply high-quality copper or graphite-based grease to all connections.

Ensure tight coupling: Never drill with loose joints, as this causes rapid thread deformation.

Regular Inspection: Replace rods when the thread profile shows significant thinning to avoid breaking a rod inside the hole.

Selection depends on your rock drill's power and the required hole depth.

For standard benching, T38-D38-T38 Extension Rods are common. If you prioritize drilling speed and ease of handling, MF Rods are recommended.

For high-precision deep holes, we suggest incorporating at least one Guide Tube into your drill string.