Product Description

RockHound T38 Guide Rods and Guide Tubes (D56) are specifically engineered for high-precision bench drilling and long-hole underground mining. In complex rock formations, maintaining hole straightness is the biggest challenge; our T38 series acts as a stabilizer, minimizing deviation and ensuring your drill string stays perfectly on course.

Manufactured using premium ZK22CrNi3Mo nickel-chromium-molybdenum alloy steel, these tools are built to withstand the intense impact energy of modern hydraulic top hammers. Whether you are using Epiroc, Sandvik, or other major rig brands, our T38-D56 series ensures seamless compatibility and maximized penetration rates.

Premium Material: ZK22CrNi3Mo

The soul of our drill tools lies in the steel. ZK22CrNi3Mo is a high-grade alloy steel renowned for:

High Impact Toughness: Absorbs high-frequency shock waves without fracturing.

Superior Fatigue Strength: Extends the service life under high-stress drilling conditions.

Carburizing Excellence: Optimized for surface hardening, ensuring the threads remain wear-resistant while the core stays flexible.

Key Features

Enhanced Hole Straightness: The D56 (56mm) outer diameter provides maximum rigidity to prevent the bit from wandering.

Precision CNC Machined Threads: Ensures easy coupling and uncoupling, reducing downtime and thread stripping.

Advanced Heat Treatment: Full-length carburizing and shot peening for maximum surface hardness and durability.

Optimized Flushing Hole: Large internal diameter ensures efficient debris removal and cools the drill bit during deep-hole operations.

Technical Specifications

Based on the T38-D56-T38 series, here are the technical parameters:

| Model / Part Number | Length (mm) | Length (ft) | Diameter (mm) | Diameter (inch) | Thread Type | Weight (kg) |

|---|---|---|---|---|---|---|

| 200-5612-7676 | 1220 mm | 4′ | 56 mm | 2 1/4″ | T38 | 12.6 kg |

| 200-5615-7676 | 1525 mm | 5′ | 56 mm | 2 1/4″ | T38 | 14.0 kg |

| 200-5618-7676 | 1830 mm | 6′ | 56 mm | 2 1/4″ | T38 | 17.4 kg |

Applications

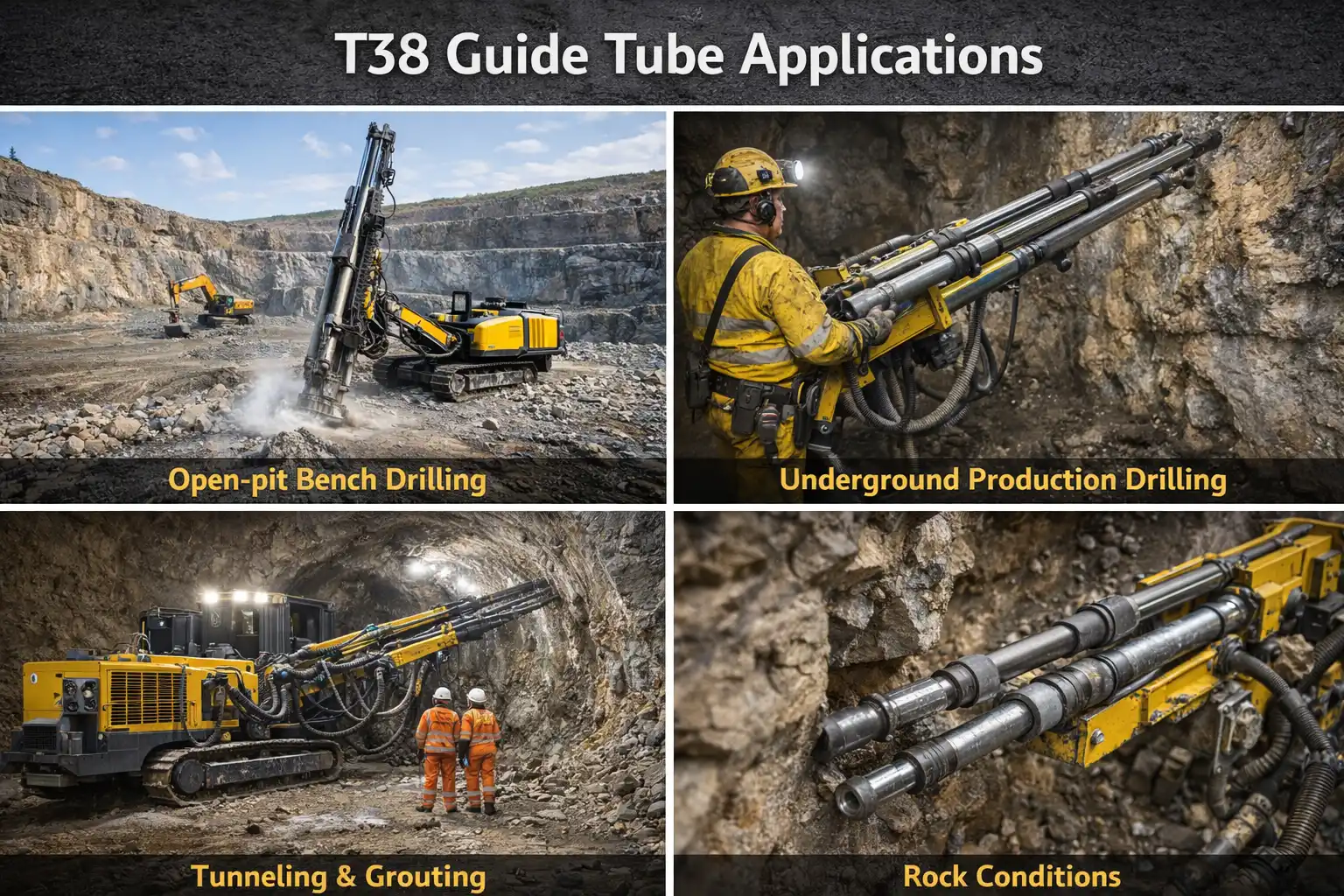

The T38 Guide Tube is indispensable for the following operations:

Open-pit Bench Drilling: For quarrying and large-scale blasting.

- Tunneling & Grouting: Provides the precision needed for reinforcement bolts.

- Underground Production Drilling: Essential for long-hole stoping.

Rock Conditions: Best suited for soft, fractured, or abrasive rock where hole deviation is common.

Maintenance

To maximize the ROI of your T38 Guide Rods, follow these industry best practices:

Thread Lubrication: Always use high-quality thread grease to prevent “cold welding” and premature wear.

Rotation Check: Regularly inspect the guide tube for excessive surface wear or bending.

Proper Storage: Store rods horizontally in a dry area to prevent corrosion and structural warping.

Coupling Tightness: Ensure all connections are tightened to the recommended torque to avoid thread damage during impact.

FAQ

A T38 Guide Tube is a specialized component positioned between the drill bit and the first drill rod. Its primary function is to enhance the rigidity of the drill string. With an outer diameter (such as D56) that closely matches the drill bit, it acts as a stabilizer to prevent "wandering" in complex rock formations, ensuring superior hole straightness.

ZK22CrNi3Mo is a premium Ni-Cr-Mo alloy steel designed for extreme conditions. Unlike standard carbon steel, it offers exceptional impact toughness and fatigue resistance. This allows our T38 Guide Rods to withstand high-frequency shock waves from modern hydraulic drifters without premature fracturing, significantly extending service life and reducing your total cost per meter.

- T38 Guide Tube: Features a hollow, tube-like structure with a larger outer diameter (e.g., 56mm). It is the preferred choice for large-hole drilling where maximum straightness and high-volume flushing are required.

T38 Guide Rod: Functions similarly to a reinforced drill rod with higher bending resistance. Both tools are engineered to solve drilling deviation issues; the choice depends on your specific rig pressure and rock hardness.

Absolutely. RockHound T38-D56 series is manufactured to strict international thread standards using high-precision CNC machining. They are 100% interchangeable with Epiroc, Sandvik, Montabert, and other leading global brands of top hammer drilling rigs.

Precision is profit. Straighter holes lead to a more uniform burden and spacing, which optimizes explosive distribution. By using T38 Guide Tubes to minimize deviation, you reduce "dead holes" and secondary breaking costs, leading to more efficient fragmentation and lower energy consumption during crushing.

To ensure peak performance and longevity:

- Thread Lubrication: Apply high-quality thread grease before every connection to prevent "cold welding" or galling.

- Visual Inspection: Regularly check for surface wear and any signs of hairline cracks in the thread roots.

- Avoid Blank Firing: Never operate the hammer without resistance, as this sends damaging shock waves through the alloy structure.

RockHound offer standard lengths including 1220mm (4'), 1525mm (5'), and 1830mm (6') as seen in our catalog. As a direct manufacturer, we also provide customized solutions for specific outer diameters or lengths to match your unique geological requirements or rig configurations.