T38 Thread Button Bit Description

RockHound T38 Thread Button Bits and Retrac Bits are engineered for high-efficiency top hammer drilling in mining, quarrying, and civil engineering. Manufactured with premium 45CrNiMo1V alloy steel, these bits offer exceptional fatigue resistance and toughness, ensuring maximum service life even in the most abrasive rock formations.

Available in diameters from 64mm to 70mm (up to 76mm), RockHound’s T38 bits feature various face designs including Standard, Drop Center, and Retrac to optimize hole straightness and flushing efficiency in different geological conditions.

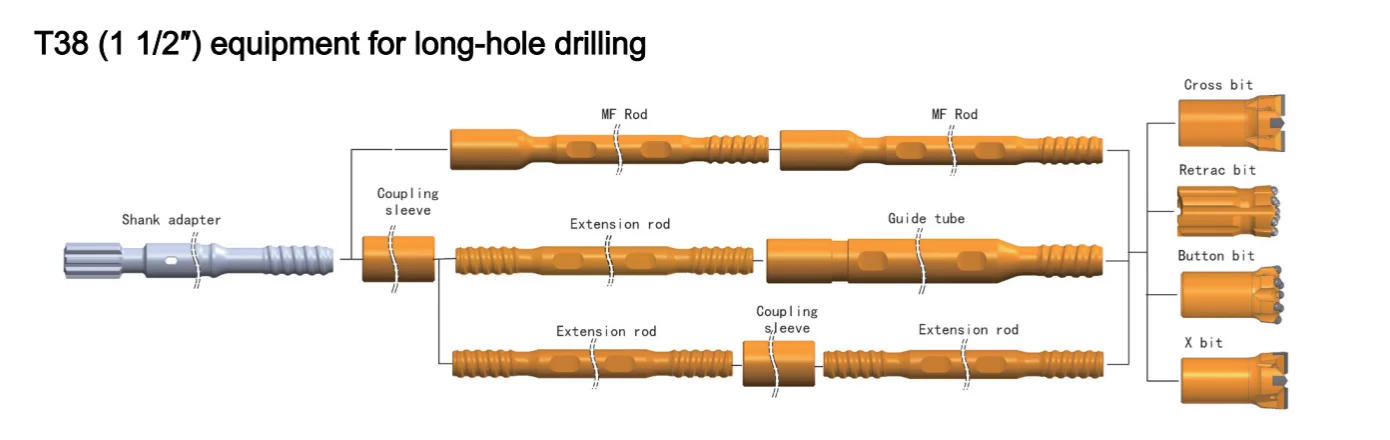

T38 Equipment For Long-Hole Drilling

Material & Key Features

Premium 45CrNiMo1V Steel: High-grade alloy body provides superior strength and prevents body premature failure under high-impact loads.

Superior Carbide Buttons: Equipped with high-quality YK05 tungsten carbide inserts (ballistic or spherical) for maximum wear resistance and penetration rates.

Optimized Face Designs:

- Standard/Flat Face: Best for hard to very hard rock.

Drop Center: Excellent for medium to hard rock, providing superior hole straightness.

Retrac Design: Features a longer, fluted back end to assist in bit retrieval in broken or caving ground.

Precision T38 Threads: Ensures a tight, reliable connection with T38 extension rods and MF rods for efficient energy transmission.

Enhanced Flushing: Strategic layout of flushing holes ensures rapid removal of cuttings, reducing regrinding and heat buildup.

Specifications

T38 Thread Button Bits(Standard & Drop Center)

| Bit Type | Diameter (mm) | Diameter (inch) | Buttons (Gauge × Centre) | Gauge Angle | Product Code | Weight (kg) |

|---|---|---|---|---|---|---|

| Standard Button | 64 | 2 1/2 | 6×12 / 3×11 | 30° | 173-6409-7663 | 1.9 |

| Standard Button | 70 | 2 3/4 | 8×10 / 6×10 | 35° | 173-7014-7665 | 2.3 |

| Standard Button | 76 | 3 | 7×12 / 4×11 | 35° | 173-7611-7665 | 3.3 |

| Drop Center | 64 | 2 1/2 | 6×11 / 4×10 | 35° | 175-6410-7665 | 1.7 |

| Drop Center | 70 | 2 3/4 | 8×10 / 6×10 | 35° | 175-7014-7665 | 2.0 |

T38 Retrac Bits (Flat & Drop Center)

| Bit Type | Diameter (mm) | Diameter (inch) | Buttons (Gauge × Centre) | Gauge Angle | Product Code | Weight (kg) |

|---|---|---|---|---|---|---|

| Flat / Retrac | 64 | 2 1/2 | 4×10 / 8×10 | 30° | 174-6412-7603 | 1.9 |

| Flat / Retrac | 70 | 2 3/4 | 6×10 / 8×10 | 35° | 174-7014-7605 | 2.3 |

| Drop Center / Retrac | 64 | 2 1/2 | 6×11 / 4×10 | 35° | 176-6410-7605 | 1.7 |

Applications

RockHound T38 bits are optimized for a wide range of top hammer drilling applications:

-

Mining: Underground production drilling and long-hole blasting.

-

Quarrying: Bench drilling in aggregate and limestone production.

-

Construction: Tunneling, site preparation, and slope stabilization.

-

Rock Conditions: Highly effective in medium-hard to very hard, abrasive, or fractured rock formations.

-

Compatibility: Fully compatible with rock drills from Epiroc (Atlas Copco), Sandvik, Montabert, and Furukawa.

How to Maintenance T38 Thread Button Bits?

To maximize the lifespan of your 45CrNiMo1V T38 bits:

-

Timely Sharpening: Do not over-drill. Sharpen buttons when they reach about 1/3 of their original height to prevent “anti-sharpening” and button failure.

-

Thread Lubrication: Always use high-quality thread grease to prevent galling and ensure easy uncoupling from the rod.

-

Correct Drilling Pressure: Maintain stable feed pressure; excessive pressure can cause carbide breakage, while too little can lead to premature thread wear.

-

Flushing Inspection: Ensure water or air flushing is constant during drilling to keep the bit face cool and clean.

-

Storage: Store in a dry environment and apply anti-rust oil if not in use for extended periods.

Bundle Purchase Suggestion

Pairing the right bit with the right rod is crucial for drilling performance. Offer these bundles to increase your Average Order Value (AOV).

Option A: The Efficiency Bundle (For Bench Drilling)

Bit: T38-64mm Standard Button Bit.

Benefit: MF rods eliminate the need for coupling sleeves, ensuring faster rod changes and higher energy efficiency.

Option B: The Precision Bundle (For Deep Hole Drilling)

Bit: T38-64mm Drop Center Retrac Bit.

Benefit: The Drop Center bit combined with a rigid Guide Tube ensures maximum hole straightness and easy retrieval in complex rock layers.

FAQ

45CrNiMo1V is a premium high-performance alloy steel known for its exceptional toughness and fatigue strength.

During the high-frequency impacts of top hammer drilling, this material effectively prevents premature body cracking or catastrophic breakage.

Compared to standard steel grades, it significantly extends the bit's service life in hard and abrasive rock environments.

RockHound Retrac Bit is characterized by its specialized fluted or grooved skirt design at the rear of the bit body.

Its primary function is to assist in retrieving the bit more easily from broken, loose, or caving rock formations.

If your drilling operations frequently encounter "stuck" tools or difficulty in pulling the drill string back, switching to a Retrac design can drastically reduce downtime and the risk of lost equipment.

- Drop Center Design: This configuration provides excellent flushing efficiency and superior hole straightness. It is the preferred choice for medium-to-hard rock when high precision and minimal hole deviation are required.

Flat Face Design: Best suited for extremely hard and abrasive rock formations. The flat surface allows for a higher density of carbide buttons, providing greater impact resistance and wear durability.

Yes. RockHound's T38 bits are manufactured to strict industry-standard thread dimensions. They are 100% interchangeable and compatible with top hammer drill rigs from major brands, including Sandvik, Epiroc (Atlas Copco), Furukawa, and Montabert. They can be used directly with your existing T38 extension rods and shank adapters.

The number and arrangement of tungsten carbide buttons vary by model to optimize performance:

64mm Bits: Typically feature 6 gauge buttons and 3 to 4 center buttons.

70mm Bits: Usually configured with 8 gauge buttons and 6 to 8 center buttons.

Gauge Angles: Gauge button angles typically range between $30^\circ$ and $40^\circ$ to ensure stable rock cutting and efficient energy distribution.

You should sharpen the tungsten carbide buttons when the wear flat reaches approximately 1/3 of the button diameter or when you notice a significant drop in the penetration rate. Drilling with over-worn buttons leads to uneven stress on the bit body, which can cause carbide fracturing or bit body failure. Regular maintenance can improve total drilling meters by over 20%.

- Button Chipping: Often caused by over-drilling or excessive feed pressure; ensure regular sharpening and adjust drilling parameters.

- Thread Galling: Usually due to insufficient lubrication or loose connections; always apply high-quality thread grease before coupling.

- Flushing Hole Blockage: Leads to bit face overheating; always verify that water or air flushing is clear before starting the drill.