Description

The T45 threaded button drill bit is a high-strength drilling tool commonly used for hard rock drilling, and is used in conjunction with T45 threaded couplings. Its diameter typically ranges from 76mm to 89mm, and common designs include flat-faced and Retrac (retractable) types.The button head can be designed with spherical or parabolic teeth to improve drilling efficiency and wear resistance.

This drill bit is widely used in tunnel excavation, large open-pit mines, and underground copper and gold mines, and is characterized by its fast drilling speed, long service life, and stable performance.

Material & Structure Features

The drill bit body material is 45CrNiMo1V.

The alloy is YK05.

- Retrac drill bits focus on efficient chip removal during operation

- In mining operations, retrac drill bits, through their optimized chip removal design

- Retrac bits can effectively reduce the accumulation of waste chips and improve drilling efficiency.

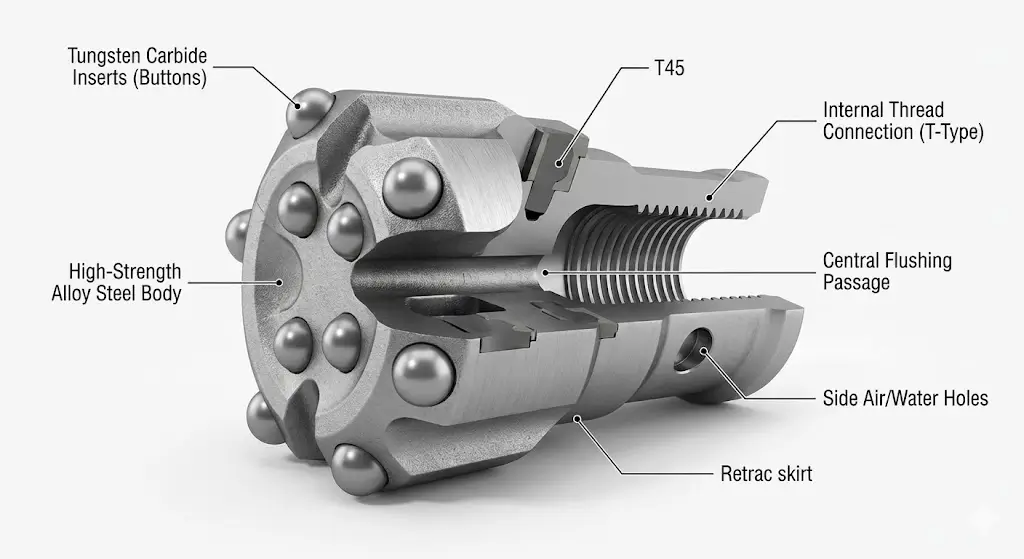

This diagram illustrates the high-performance design of a professional-grade thread button drill bit:

Tungsten Carbide Inserts (Buttons)

- Features: Uses high-purity tungsten carbide as cutting teeth, possessing extremely high hardness and wear resistance.

- Advantages: Maintains a very long service life in hard rock and highly abrasive rock formations, reducing downtime for replacement.

High-Strength Alloy Steel Body

- Features: The drill bit body is made of high-grade alloy steel with precision heat treatment.

- Advantages: Can withstand the high-frequency impact loads generated by the rock drill, has high fatigue strength, and prevents body cracking.

Internal Thread Connection (T-Type)

- Features: The diagram shows a standard T45 internal thread connection.

- Advantages: Provides a tight connection and high energy transfer efficiency, is easy to disassemble, and is compatible with mainstream rock drilling equipment.

Central Flushing Passage

- Features: A vertical fluid channel running through the center of the drill bit.

- Advantages: Provides strong water/air pressure to quickly remove rock cuttings from the cutting face, preventing secondary crushing and improving drilling efficiency.

Side Air/Water Holes

- Features: Auxiliary flushing ports located on the side of the drill bit.

- Advantages: Works in conjunction with the central channel to create a vortex effect, ensuring smooth chip removal even in deep hole drilling, preventing drill bit jamming.

Retrac Skirt

- Features: The skirt has a specific ribbed structure.

- Advantages: Easier to retrac the drill bit in loose or fractured rock formations, reducing the risk of drill bit loss and jamming.

Specification

T45 Thread Button Bit Technical Specifications

| Bit Type | Diameter (D) | Buttons (No x Size.mm) | Gauge Angle | Thread | Product Code | Weight (kg) | ||

|---|---|---|---|---|---|---|---|---|

| mm | inch | Gauge | Centre | |||||

| T45 Standard Button Bits | ||||||||

| Button Bit | 76 | 3 | 7 x 12 | 4 x 12 | 35° | T45 | 173-7611-7705 | 2.4 |

| Button Bit | 89 | 3 1/2 | 8 x 13 | 6 x 13 | 35° | T45 | 173-8914-7765 | 3.8 |

| Button Bit | 102 | 4 | 9 x 12 | 6 x 12 | 35° | T45 | 173-0215-7705 | 6.7 |

| T45 Retrac Button Bits – Flat Face | ||||||||

| Retrac Flat | 76 | 3 | 8 x 12 | 4 x 11 | 35° | T45 | 174-7612-7705 | 3.2 |

| Retrac Flat | 89 | 3 1/2 | 9 x 11 | 6 x 10 | 35° | T45 | 174-8915-7705 | 4.2 |

| T45 Retrac Button Bits – Drop Center | ||||||||

| Retrac Drop Center | 70 | 2 3/4 | 6 x 11 | 4 x 10 | 40° | T45 | 176-7010-7704 | 2.2 |

| Retrac Drop Center | 89 | 3 1/2 | 8 x 12 | 6 x 11 | 35° | T45 | 176-8914-7705 | 3.8 |

| Retrac Drop Center | 102 | 4 | 8 x 13 | 7 x 12 | 35° | T45 | 176-0215-7705 | 5.3 |

| T45 Insert X Bit | ||||||||

| X Bit | 89 | 3 1/2 | Insert: 16 x 10 (H x T) | – | T45 | 168-8916-7710 | 5.0 | |

Applications

The T45 Thread Button Bit is a heavy-duty rock drilling tool designed for medium to hard rock formations. As a core component of top hammer drilling systems, it is widely utilized in high-impact environments where precision and durability are paramount.

Primary Applications

Bench Drilling: T45 bits are the industry standard for production drilling in open-pit mines and quarries, offering straight holes and high penetration rates.

Long-hole Drilling Underground : Its robust thread design ensures stable energy transmission, making it ideal for underground mining production.

Tunneling & Drifting: The T45 retrac bit design is specifically engineered to prevent jamming in fractured rock zones during tunnel construction.

Construction & Infrastructure : Used extensively for anchoring, foundation reinforcement, and road construction projects.

Suitable Rock Formations

RockHound T45 bits, featuring premium tungsten carbide inserts, are optimized for:

Hard Rock: Granite, basalt, and quartzite.

Medium-Hard Rock: Limestone, sandstone, and hard shale.

Abrasive Formations: Highly abrasive ground where gauge wear is a concern.

Why Choose T45 Retrac Bits for Your Project?

Enhanced Flushing: Designed with multiple flushing holes to efficiently remove drill cuttings, reducing secondary wear.

Superior Retraction: The Retrac design features a tapered back end, allowing for easier retrieval of the drill string in loose or collapsing ground.

Maximum Energy Transfer: The T45 thread profile is precision-machined via CNC to ensure a tight connection with the drill rod, minimizing energy loss.

How does RockHound T45 Drill Bit Work

Working Principle

- Medium-hard to hard rock formations: The rock in the video is hard and contains fractured zones.

- Underground mining and tunnel excavation: Used for medium-depth drilling, especially in applications requiring high hole straightness.

- Loose/unstable formations: This is the “core strength” of the easily retrievable drill bit. In conditions where the rock is prone to collapse or the borehole wall is unstable, conventional drill bits are highly susceptible to jamming, while the easily retrievable drill bit can effectively handle these situations.

"Retrac" Retractable Design:

Principle: The drill bit skirt features long longitudinal alloy cutting teeth or stepped edges.

High-Energy Power Transmission:

Principle: T45 represents a 45mm thread specification. This large thread design can withstand the high-frequency impact waves generated by modern high-power rock drills.

Efficient Chip Removal System:

Principle: The video shows high-pressure water/air jets used to flush the bottom of the hole.

Advantages: When drilling is complete and the drill bit needs to be retracted, if the borehole wall collapses or rock cuttings accumulate, the reverse cutting edges on the skirt can “grind” away the obstacles behind it, ensuring the drill rod is pulled out smoothly.

Advantages: As seen in the video, the powerful impact force is efficiently transmitted through the T45 thread to the ball teeth on the drill bit face, causing the rock to break.

Advantages: The retractable drill bit’s skirt has deeper grooves, which, in conjunction with the central chip removal hole, can remove crushed rock more quickly, reducing secondary wear and preventing jamming caused by accumulated debris.

FAQ

T45 drill bits are industry-standard tools for bench drilling, long-hole drilling, and tunneling. They are designed to be compatible with high-power top hammer rock drills and hydraulic drifters. These bits are ideal for medium to hard rock formations in surface mining and quarrying operations.

RockHound offer a comprehensive range of diameters to suit various blasting requirements, including:

76mm (3") - Standard for smaller hole blasting.

89mm (3 1/2") - The most popular size for general production drilling.

102mm (4") - Ideal for large-scale quarrying and mining projects.

Standard T45 Bits: Feature a compact body design, best suited for stable and homogeneous rock formations where the risk of hole collapse is low.

T45 Retrac Bits: Specifically designed for fractured or broken rock. The "Retrac" (retractable) skirt features cutting edges or grooves that help the bit drill its way out of a hole if the rock collapses behind it, significantly reducing the risk of stuck drill strings.

Drop Center (DC): Features a recessed center. It is excellent for maintaining hole straightness and is preferred for fast drilling in soft to medium-hard rock.

Flat Face (FF): This design provides a stronger bit body and is more durable in extremely hard or abrasive rock conditions.

The configuration of Tungsten Carbide inserts is critical for efficiency. For example:

RockHound T45-102mm Standard Bit uses a 9 x 12mm Gauge + 6 x 12mm Centre layout. The higher number of gauge buttons ensures better diameter retention and wear resistance in abrasive ground.

The T45 Insert X Bit (89mm) utilizes cross-type inserts for specific impact requirements where button bits might suffer from premature insert failure.

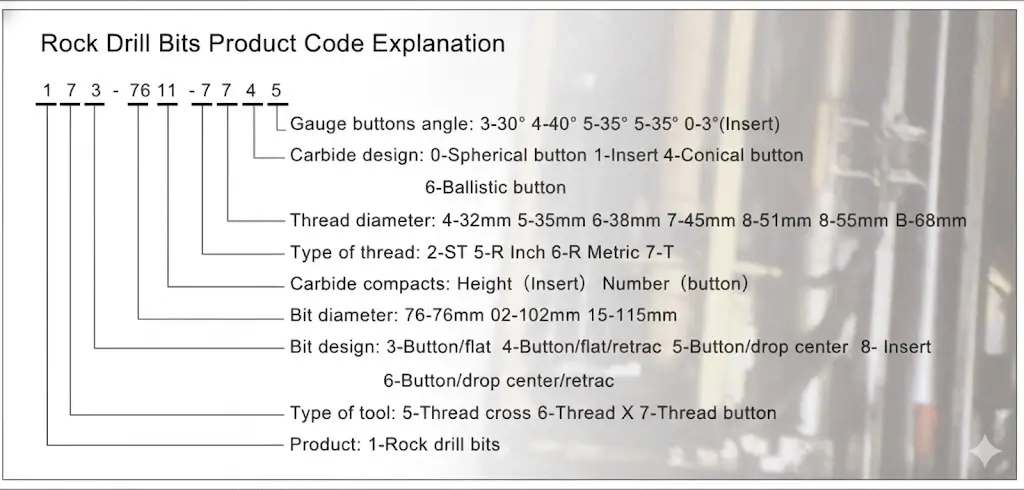

RockHound T45 series is categorized by series numbers for easy identification:

173-XXXX-XXXX: T45 Standard Button Bits.

174-XXXX-XXXX: T45 Retrac Bits – Flat Face.

176-XXXX-XXXX: T45 Retrac Bits – Drop Center.

168-XXXX-XXXX: T45 Insert X Bits.

You can contact our sale-manager to tell the Code you need.