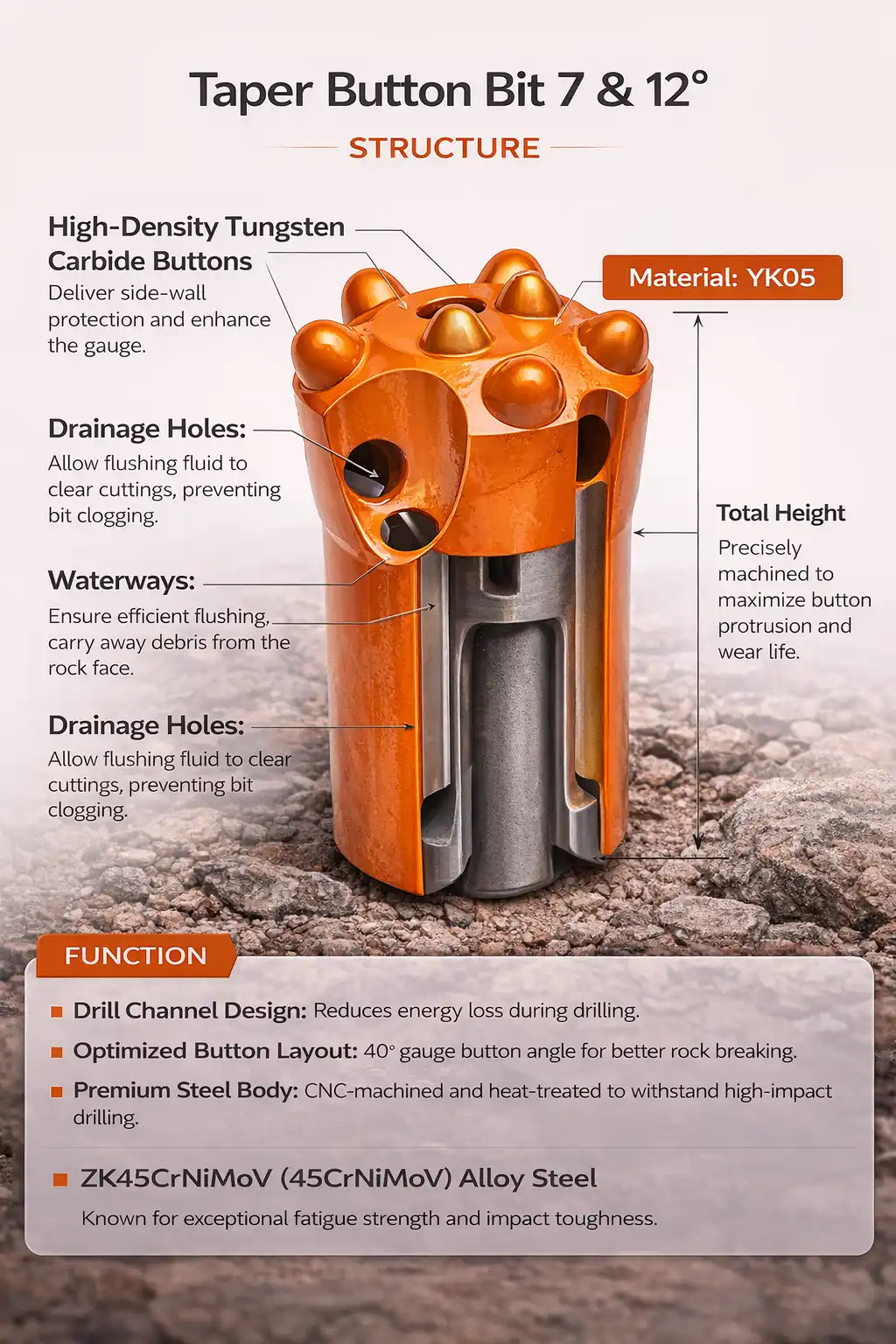

RockHound Taper Button Bits are specifically engineered for high-performance small hole drilling. Unlike standard bits, these are forged from ZK45CrNiMoV (45CrNiMoV)—a premium alloy steel known for its exceptional fatigue strength and impact toughness.

Combined with high-density tungsten carbide buttons, these bits are designed to withstand the most abrasive rock conditions, ensuring faster penetration rates and a significantly longer service life. Whether you are using a 7° taper for light pneumatic drills or a 12° taper for heavy-duty hydraulic rigs, our bits provide the precision and durability your project demands.

Key Features

High-Grade Material: Manufactured using ZK45CrNiMoV alloy steel, providing superior resistance to body breakage and wear.

Optimized Button Layout: Features a 40° gauge button angle for efficient rock breaking and smoother flushing.

Dual Taper Options: Available in both 7° and 12° tapers to ensure perfect compatibility with various taper drill rods.

Precision Engineering: CNC-machined bodies and heat-treated for maximum structural integrity.

Enhanced Productivity: Designed for “Small Hole Drilling,” reducing energy loss and increasing drilling speed in medium to hard rock.

Structure & Function

| Component | Material | Main Function |

|---|---|---|

| Flushing Hole | — | Debris removal, cooling, pressure release |

| Flushing Groove | — | Fluid distribution, cuttings removal |

| Tungsten Carbide Buttons | YK05 | Rock crushing, exceptional wear resistance in abrasive formations |

| Bit Body | 45CrNiMoV | Structural support, high impact resistance and fatigue strength |

| Taper Connection | 45CrNiMoV | Efficient energy transfer, secure rod connection and torque transmission |

Technical Specifications

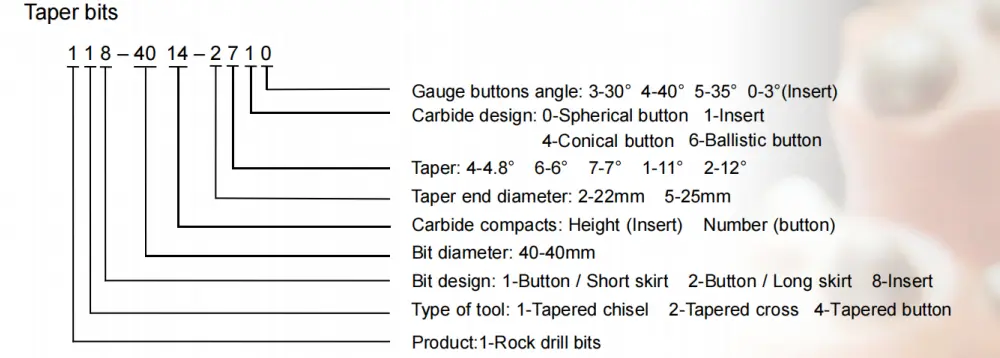

Taper Bits Code Example:

| Product Code | Diameter (mm/inch) | Buttons (Gauge × Centre) | Gauge Angle | Taper | Weight (kg) |

|---|---|---|---|---|---|

| 141-3208-2264 | 32mm (1 1/4″) | 6×7 / 2×7 | 40° | 12° | 0.3 |

| 142-3508-2264 | 35mm (1 3/8″) | 6×8 / 2×7 | 40° | 12° | 0.3 |

| 141-3808-2764 | 38mm (1 1/2″) | 6×9 / 2×8 | 40° | 7° | 0.4 |

| 141-4008-2764 | 40mm (1 9/16″) | 6×9 / 2×8 | 40° | 7° | 0.4 |

| 141-4108-2764 | 41mm (1 5/8″) | 6×9 / 2×8 | 40° | 7° | 0.4 |

| 141-4208-2764 | 42mm (1 21/32″) | 6×9 / 2×8 | 40° | 7° | 0.5 |

Application

These taper bits are the preferred choice for:

- Underground Mining:For blasting holes and bolt hole drilling.

- Quarrying: Dimension stone industry and aggregate production.

- Construction: Tunneling, road work, and foundation drilling.

- Small Hole Projects: Small hole diameters between 32mm and 42mm.

How To Maintenance

Regrind Timely: Do not wait for the buttons to be completely flat. Regrinding the carbides when wear reaches 1/3 of the diameter maintains efficiency.

Socket Cleaning: Before connecting to the taper rod, ensure the bit’s internal taper and the rod’s end are free of debris to prevent premature failure.

Proper Flushing: Always ensure adequate water or air pressure to clear cuttings and cool the bit head.

Avoid Dry Drilling: Never drill without coolant, as it can cause the ZK45CrNiMoV steel to lose its temper and lead to carbide pops.

How to Choose the Right Taper Button Bits?

The Angle:

12° Taper: Better suited for heavy-duty drilling or very hard rock where higher impact energy is present.

7° Taper: Generally used with lighter pneumatic rock drills (like YT24/YT28).

The Diameter: Match the bit diameter to your blasting requirements. 32mm-35mm is common for tight patterns, while 38mm-42mm is standard for general mining.

The Rock Type: For extremely abrasive rock, ensure you select the $6 \times 9$ gauge button configuration for better side-wall protection.

FAQ

ZK45CrNiMoV (45CrNiMoV) is a high-grade alloy steel specifically designed for heavy-impact environments. Compared to standard carbon steel, it offers significantly higher fatigue strength and impact toughness. This means the bit body is much less likely to crack or break even when drilling through extremely hard or abrasive rock formations.

The choice depends on your drilling equipment and rock hardness:

7° Taper: The most common standard, ideal for lightweight pneumatic handheld rock drills (like the YT24 or YT28 series) used in medium-hard rock.

12° Taper: Designed for more powerful hydraulic drilling rigs or very hard, abrasive ground. The 12° angle provides a more robust connection to handle higher impact energy. Our 32mm and 35mm bits are available in 12°, while 38mm to 42mm bits typically feature a 7° taper.

All our taper button bits in this series feature a 40° gauge button angle. This specific geometry is engineered to optimize rock-breaking efficiency at the edge of the hole, ensuring a cleaner hole profile and reducing the "pinching" effect on the bit, which extends the tool's life.

These bits are designed for portability and efficiency. Depending on the diameter, the weight ranges from 0.3 kg (for 32mm/35mm sizes) to 0.5 kg (for the 42mm size).

Each bit size has a unique product code for precision ordering. For example, the 40mm bit with a 7° taper is coded as 141-4008-2764. Please refer to our Specification Table above to match the diameter and taper angle to the correct code.