Table of Contents

What is the Rock Dirll Button Bit?

A rock drill button bits is a tool to break and penetrate rocks,which has a wide applications,like mining, geological exploration, tunneling, construction,etc,. The requirements for drill button bits in rock drilling work are: reasonable shape and structure, fast rock drilling speed, strong endurance.

In addition, good powder discharge performance, long service life, easy manufacturing and grinding, and low cost also important.

Boost drilling efficiency with RockHound high-performance rock drill bits. Durable, fast, and cost-effective tools for mining, tunneling, and construction.

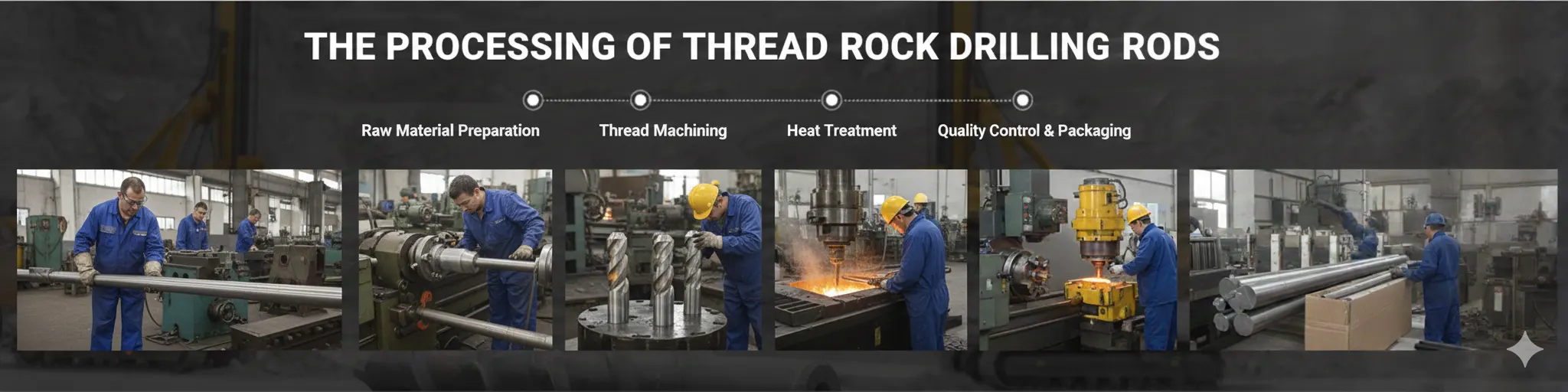

Step1.Raw Material Specifications and Preparation

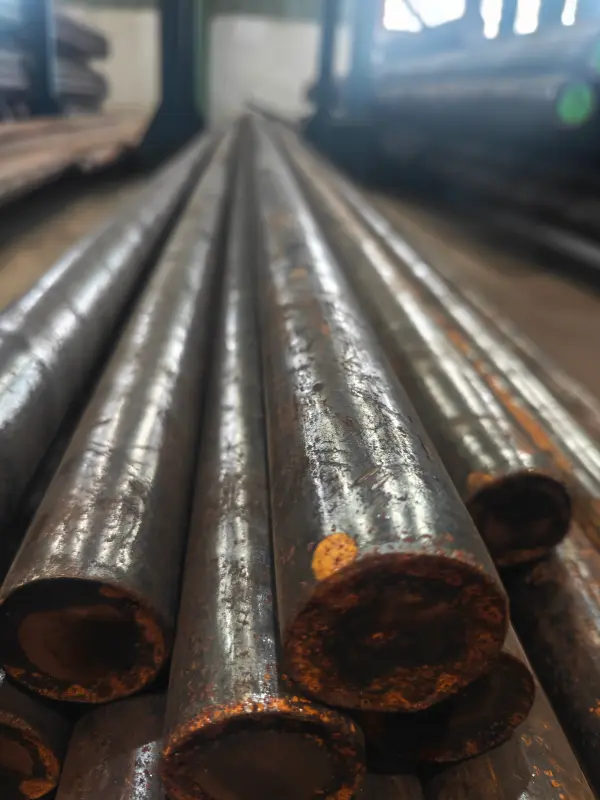

Threaded Button Bit Body (Cabin) Material

45CrNiMo1V: High-strength Chromium-Nickel-Molybdenum-Vanadium Alloy Steel.

Alloy Grade: YK05

Cutting Process: High-precision CNC metal band saw is used. Cutting is performed according to standard tolerance requirements to ensure end-face flatness.Provide a reference for subsequent processing.

Material list for the lug body is as follows:

| Product Name | Specifications | Material Grade | Standard | Production Date | Inspection Date | Quantity | Final Result | |

|---|---|---|---|---|---|---|---|---|

| Drifting Rod | H25×2000(2500)-R25 | ZK22CrNi3Mo | Q/JSGB6-2011 | 2025-12-02 | 2025-12-05 | 5 PCS | QUALIFIED | |

| Chemical Composition Analysis (%) | ||||||||

| Element | C | Si | Mn | Cr | Mo | Ni | Ti | Al |

| Content (%) | 0.22 | 0.30 | 0.73 | 1.34 | 0.25 | 3.05 | 0.003 | 0.026 |

| Trace Elements | S | P | Cu | As | Sn | Testing Conclusion | ||

| Content (%) | 0.014 | 0.01 | 0.04 | 0.005 | 0.004 | PASS | ||

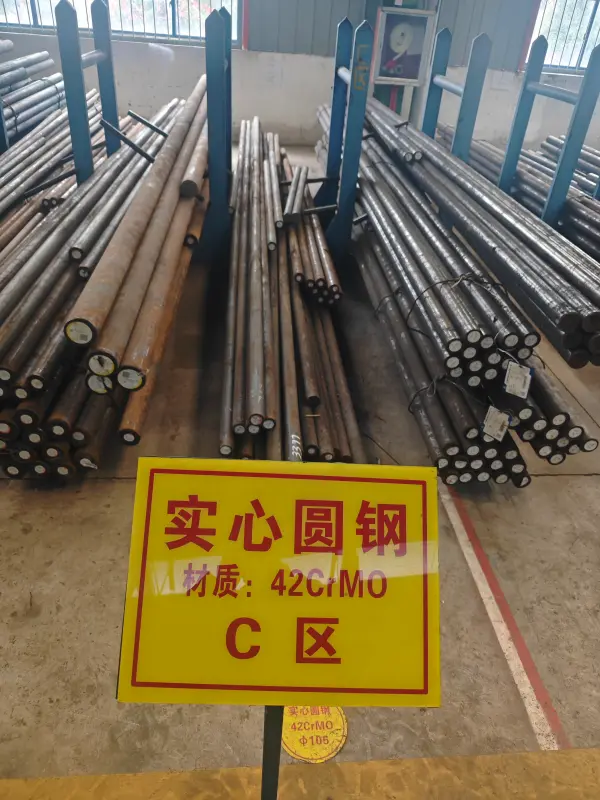

Tapered Drill Bits Body (Cabin) Material

45CrNiMoVa, 42CrMo, 35CrMo

Alloy Grades: YK05, KK06H

Step2.Preliminary Machining

Peeling Process

Commonly known as skinning, machining the outer edge.

Remove the decarburized layer and defects from the raw material surface, perform rough machining of the outer diameter, leave allowance for finishing, and initially calibrate the head cutting angle.

CNC Machining

Powder Discharge Tank Machining:

Optimized streamlined design to ensure smooth slag discharge.

Ventilation/Drainage Holes:

Deep hole drilling to ensure center symmetry.

Thread Machining:

Standard ring gauge inspection to ensure connection strength.

Alloy Tooth Hole Machining:

Machining accuracy is controlled within ±0.02mm to ensure the stability of the interference fit.

Step3.Vacuum Heat Treatment

Heat treatment involves heating the metal to a certain temperature and then tempering it, thereby changing the internal structure of the metal, increasing hardness, relieving stress, and increasing toughness. Using a vacuum furnace can prevent oxidation.

Process objective: Completed in a vacuum environment (pressure < 10⁻² Pa) to completely eliminate surface oxidation and decarburization.

Vacuum Quenching: By precisely controlling the heating curve and cooling rate, the base material hardness reaches HRC 45-50 (adjusted according to specific models), improving fatigue strength.

High-Tempering: Eliminates machining and quenching internal stresses, improves base material toughness, and ensures no fracture under heavy-load impact conditions.

Step4.Tooth Setting Process

Alloy teeth are installed inside the drill bit body’s tooth bore. The process involves placing the alloy teeth into the heated drill bit body’s tooth bore and manually inserting them by hammering. The hammering direction can be manually adjusted to ensure smooth entry of the alloy teeth into the hole.

Through the principle of thermal expansion and contraction, the drill bit body encapsulates the alloy. The size of the alloy is ground according to the actual size of the drill hole to achieve a perfect match. A copper sheet is inserted between the alloy and the tooth bore. The copper sheet, being ductile, provides cushioning and better conforms to the hole wall when the alloy is inserted after heating.

Advantages:High bonding strength and good stability.

Carbide Material: YG05 (ISO K05) ultra-high hardness, wear-resistant alloy.

Geometric Angles: Standard tooth angle is 35° (customizable to suit different rock formations).

Match Precision: The tooth hole and alloy are interference-fitted, with clearance accurate to 0.01mm (1 micrometer).

Brazing & Fitting: Hot-setting/brazing combined with high-frequency induction heating.

Pressure Relief: Uses copper brazing sheets (precisely ground to a fineness). Utilizing the high ductility of copper, these sheets absorb shock, cushion impacts, and protect the hole walls during impacts, preventing alloy breakage or loss.

Button Bit Technical Adaptation Guide for Diverse Geological Conditions

| Rock Formation Type | Recommended Carbide Angle | Technical Logic & Advantage | Base Body Requirements |

|---|---|---|---|

|

Extremely Hard Rock (e.g., Granite, Basalt) |

38° – 42° | Increasing the angle enhances impact toughness, effectively preventing carbide chipping or “shattering” under high-frequency, heavy-duty impacts. | Optimized Vacuum Tempering is required to ensure superior shock absorption of the steel body. |

|

Medium to Hard Rock (e.g., Limestone, Sandstone) |

35° (Standard) | The optimal balance between cutting efficiency and tool life. It is the most versatile configuration for general mining and quarrying. | Standard Shot Peening reinforcement to ensure maximum fatigue resistance. |

|

Soft or Abrasive Rock (e.g., Shale, Weathered Rock) |

30° – 33° | A sharper angle provides better penetration rates (ROP). This “aggressive” geometry maximizes productivity in softer formations. | Enlarged Flushing Grooves are recommended to prevent mud plugging and ensure smooth chip removal. |

Step5.Surface Finishing:Shot Blasting

Utilizes high-strength steel shot to impact the surface of the drill bit, removing heat-treated oxide scale and simultaneously generating surface compressive stress, significantly improving the service life of the drill bit.which prepares the surface for subsequent anti-corrosion processes.

Step6.Anti-corrosion Process:Coating & Protection

The painting workshop employs a fully automated spraying line combined with manual spraying, comprehensively ensuring the product’s corrosion resistance and visual appeal.

Corrosion Protection: Environmentally friendly electrostatic spraying or rust-preventive paint.

Color Coating: Standard colors (blue, orange, black), coating with excellent anti-adhesion properties.

Environmental standards: VOC emissions meet standards, ensuring no pollution or odor at the construction site.

Step7.Packaging & Logistics

To facilitate transportation and sales, manufacturers will package and label the products as the final step. Common packaging forms include carton packaging, wooden box packaging, pallet packaging, etc.

Unit Packaging: Thickened custom-made cardboard boxes (5-10 pieces/box), filled with shock-absorbing material.

Shipping Packaging:Export-grade fumigated wooden crates, customized according to order quantity, lined with moisture-proof film.

Value-Added Services: Laser marking (brand logo, specifications, traceability code) is available; additional processing fees apply.

Marking Specifications: 100mm*100mm.

FAQ about Rock Drill Button Bits

Drilling into hard rock is performed based on the principle of rotary percussive drilling. Top hammers are used for this purpose. Air is the flushing medium usually used to flush drill cuttings from the borehole. A dust exhaust collects the drilling dust expelled.

Cross-Type Drill Bits: Featuring a chisel-shaped tungsten carbide tip, cross-type drill bits are built for hard and abrasive rock formations. Their wear-resistant design makes them a top choice for drilling rock with a hammer drill, ideal for deep holes in challenging environments like quarries.

Drill holes: Identify strategic points on the rock and drill holes to the required depth for the hydraulic splitter. Apply hydraulic pressure: Insert the hydraulic splitter into the holes. The splitter expands, applying force to create cracks and split the rock apart.