Table of Contents

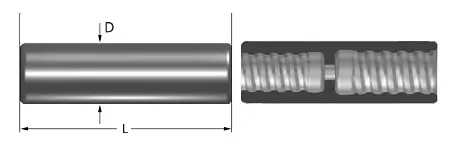

In rock drilling operations, the Rock Drill Coupling Sleeve plays a critical role in connecting drill rods and transmitting impact energy and torque from the rock drill to the drilling tools.

Its performance directly affects drilling efficiency, tool life, and overall operational cost.

To meet the demanding conditions of mining, tunneling, and construction drilling, our Rock Drill Couplings are manufactured using 22CrNi3Mo alloy steel and a strictly controlled production process.

What Is a Rock Drill Coupling Sleeve?

A Rock Drill Coupling (also known as Drill Rod Coupling or Threaded Coupling) is a mechanical connector used to join drill rods in top hammer drilling systems.

It must withstand:

High-frequency impact energy

High torque transmission

Severe wear and fatigue loads

Because of these harsh conditions, both material selection and heat treatment process are crucial.

Raw Material: 22CrNi3Mo Alloy Steel

RockHound use 22CrNi3Mo, a low-carbon alloy carburizing steel widely applied in heavy-duty rock drilling tools.

Key Features of 22CrNi3Mo

Excellent carburizing performance

High surface hardness after heat treatment

Strong and tough core to absorb impact energy

Superior fatigue resistance

Stable performance under extreme drilling conditions

This material is commonly used for rock drill rods, couplings, shank adapters, and other high-load drilling components.

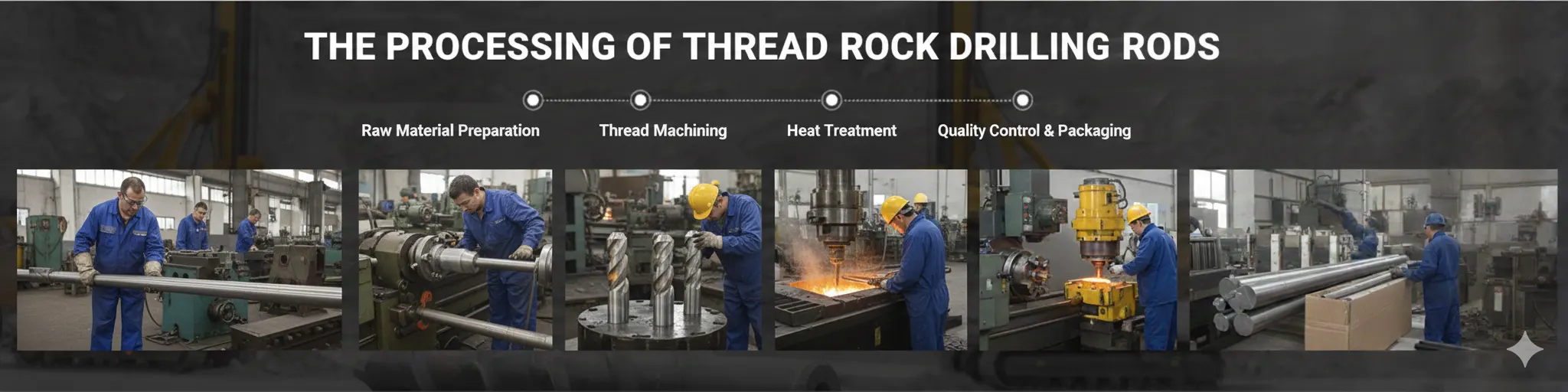

Rock Drill Coupling Manufacturing Process

Each Rock Drill Coupling is produced through a series of precision-controlled processes to ensure consistent quality and long service life.

Step1. Cutting (Raw Material Preparation)

The steel bar is cut to the required length according to technical drawings.

Accurate length control

Smooth end faces

Reduced deformation during machining

This step ensures uniformity for subsequent machining processes.

Step2. Turning & Thread CNC Machining

This is one of the most critical stages in coupling production.

Operations include:

Outer diameter turning:

Removes surface oxidation and decarburized layers to ensure material integrity.Thread machining:

Full Bridge thread

Half Bridge thread

Same diameter coupling

Different diameter coupling

All threads are machined according to rock drilling industry standards, ensuring:

Precise thread engagement

Stable torque transmission

Reduced risk of loosening or thread failure

Step3. Carburizing Heat Treatment

The coupling undergoes carburizing heat treatment, using the same process applied to drill rods.

Benefits of carburizing:

Hard, wear-resistant surface layer

Tough and impact-resistant core

Improved fatigue strength

Extended service life under high-impact drilling

This balance of hardness and toughness is essential for rock drilling applications.

Step4. Shot Blasting (Surface Treatment)

Shot blasting is performed to prepare the surface for corrosion protection.

Purpose of shot blasting:

Remove residual oxide scale and burrs

Improve surface cleanliness

Enhance coating adhesion

Achieve uniform surface texture

This step is critical for ensuring the effectiveness of the anti-corrosion coating.

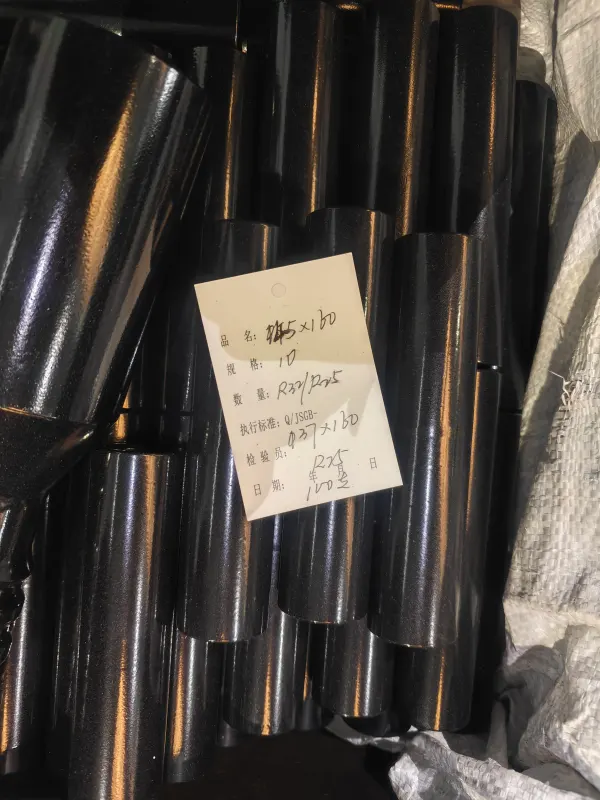

Step5. Anti-Corrosion Treatment

After surface preparation, the coupling is coated with black anti-corrosion paint.

Advantages:

Protection against rust and oxidation

Suitable for humid and dusty mining environments

Improved durability during storage and transportation

Customized surface treatments can also be provided upon request.

Step6. Packaging

All Rock Drill Couplings are packed in export-standard wooden cases.

Shock-resistant

Moisture-proof

Suitable for long-distance sea transportation

Ensures products arrive safely at the customer’s site

Types of Rock Drill Coupling Sleeves?

There are three types of coupling sleeves:

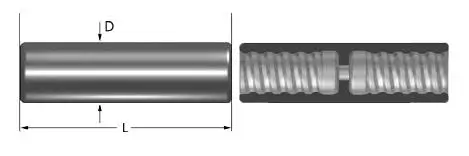

Standard coupling sleeve

Standard coupling sleeve, also known as semi bridge coupling sleeve, has a section of the bridge without a thread in the middle. The threaded part of the drill pipe cannot be screwed through the bridge part of the coupling, and the end of the thread can closely adhere to the casing bridge zone. Standard coupling sleeve is particularly suitable for high-torque drilling rigs. Most rope thread (R thread) and trapezoidal thread (T thread) coupling sleeves are with half-bridge type. The half-bridge type is by far the most widely used couplings.

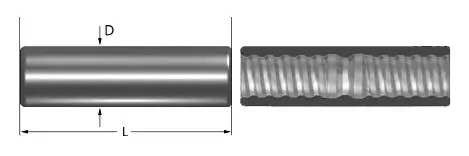

Full bridge coupling sleeve

Full bridge coupling sleeve can completely eliminate the looseness of the coupling sleeves along with the threaded connection. It is mainly used in surface mining, with better disassembly characteristics, firmer connections, and almost no clamping situation.

Crossover couplings

Crossover couplings are used to convert different thread types or thread diameter sizes.

Features of RockHound Drill Couplings

Thanks to optimized material selection and manufacturing processes, our couplings offer:

High wear resistance

Excellent impact energy transmission

Stable thread connection

Long service life

Reduced downtime and replacement costs

They are widely used in:

Mining drilling

Tunneling projects

Quarrying

Construction rock drilling

Why Choose RockHound Drill Couplings?

Proven 22CrNi3Mo alloy steel

Mature carburizing 20-hours heat treatment process

Strict quality control at every production stage

Suitable for various thread types and drilling systems

Reliable performance in harsh working conditions

Conclusion

RockHound high-quality Rock Drill Coupling is essential for efficient and reliable drilling operations.

By combining premium alloy steel, precision machining, and advanced heat treatment, we deliver Rock Drill Couplings that meet the demanding requirements of global drilling applications.

FAQ about Rock Drill Coupling Sleeve

RockHound Drill Coupling Sleeves are manufactured from 22CrNi3Mo alloy steel, a low-carbon carburizing steel widely used in rock drilling tools.

This material offers excellent wear resistance, high impact strength, and superior fatigue performance, making it ideal for harsh drilling conditions such as mining and tunneling.

Carburizing heat treatment creates a hard, wear-resistant surface layer while maintaining a tough core.

This combination allows the coupling to withstand:

High-frequency impact energy

Strong torque transmission

Long-term cyclic fatigue

Without proper carburizing, couplings may suffer from premature wear or thread failure.

RockHound can manufacture Rock Drill Coupling Sleeves with various thread designs, including:

Full Bridge thread

Half Bridge thread

Same diameter couplings

Different diameter couplings

All threads are precisely machined to ensure accurate fit and reliable performance with different drilling systems.

Yes. Our Rock Drill Coupling Sleeves are designed to be compatible with a wide range of rock drill rods and top hammer drilling systems.

We can produce couplings according to:

Standard thread specifications

Customer drawings

Customized dimensions and tolerances

Please provide your drill rod model or technical requirements for confirmation.

After shot blasting, our couplings are coated with black anti-corrosion paint, which:

Protects against rust and oxidation

Improves durability during storage and transportation

Performs well in humid and dusty environments

Alternative surface treatments are available upon request.

The service life depends on working conditions such as rock hardness, drilling parameters, and maintenance practices.

However, thanks to 22CrNi3Mo material and optimized carburizing treatment, our couplings are designed to achieve a long service life and stable performance under heavy-duty drilling conditions.

All products are packed in export-standard wooden cases, providing:

Shock protection

Moisture resistance

Suitability for long-distance sea transportation

This ensures the couplings arrive safely at the customer’s site.

Yes. RockHound support OEM and customized production, including:

Special thread types

Different diameters and lengths

Customized surface treatments

Simply share your technical drawings or application requirements with us.

RockHound Drill Coupling Sleeves are widely used in:

Mining drilling

Tunneling and underground projects

Quarrying

Construction and foundation drilling

They are designed for high-impact and high-load rock drilling applications.