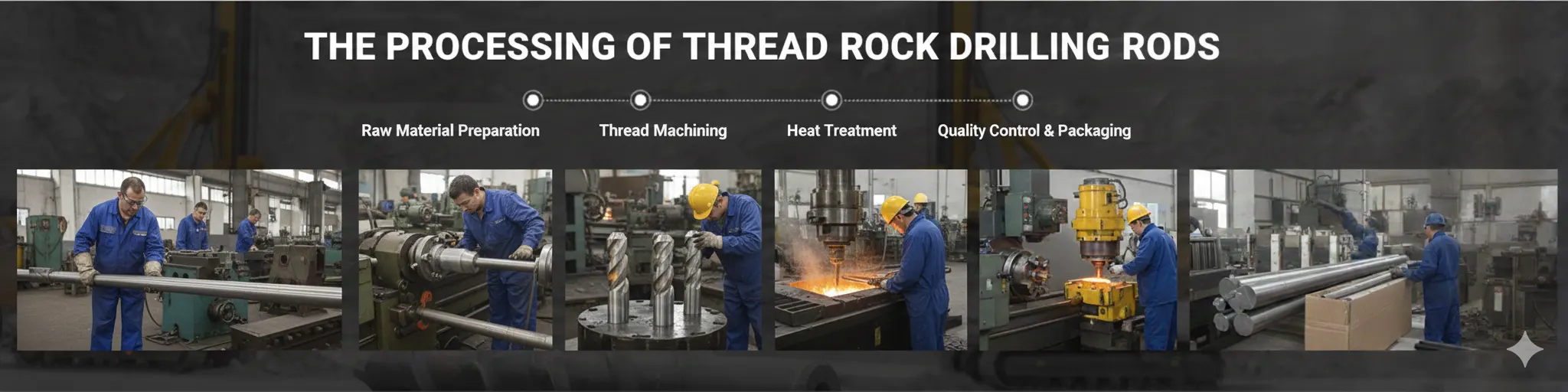

Tapered Drill Rod Process: From Raw Steel to Finished Product

Taper drill rods play a critical role in rock drilling operations such as mining, quarrying, tunneling, and construction. Their performance directly affects drilling efficiency, tool life, and operating cost.

In this article, RockHound will explain the complete manufacturing process of tapered drill rods, focusing on material selection, machining accuracy, and heat treatment technology.

Taper Drill Rod Specifications and Materials

Before machining begins, the correct specifications and steel grades must be selected to meet drilling requirements.

Common Specifications

- Shank Type: H22, H25

- Rod Length: 0.3 – 13 Meters

Steel Grades Used

- ZK55SiMnMo–Alloy steel for standard drill rods

- ZK22CrNi3Mo–Carburizing alloy steel for extended service life

These materials provide an optimal balance between strength,toughness,and wear resistance.

| Product Name | Material | Specification (mm) | Length (mm) | Features/Shank Type |

|---|---|---|---|---|

| Carburized Drill Rod | ZK22CrNi3Mo | H22 | 1328 | 108 Shank End |

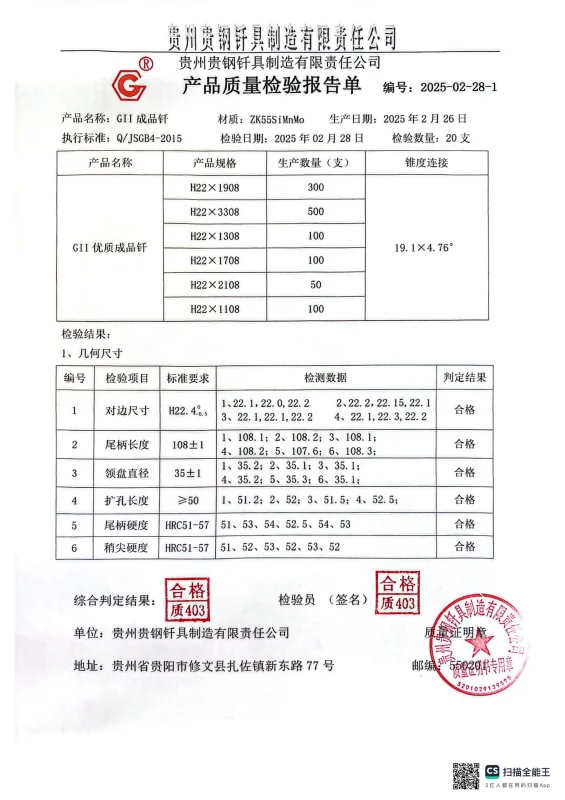

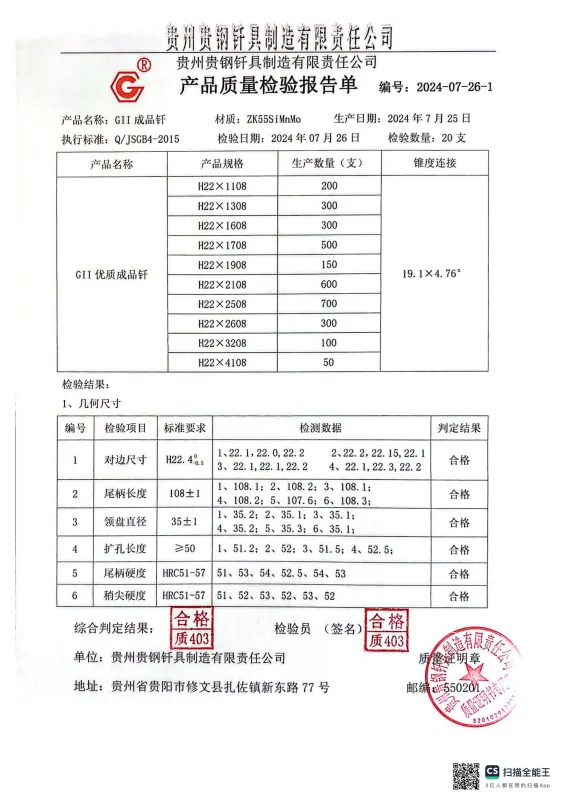

GIII High-Quality Drill Rods Certification

Step-by-Step Taper Drill Rod Production Process

Step1. Raw Material Cutting

Steel bars are cut to the required length according to customer specifications.

The cutting range covers short rods (0.3 m) to long drill rods up to 13 m, ensuring flexibility for different drilling applications.

Step2. Shank End Machining

The shank end is machined to ensure accurate fit and reliable energy transmission:

Enlarging and drilling the flushing hole

Chamfering for smooth edges

Correcting the hexagonal profile

Machining the collar (shoulder)

Advantage: Precision at this stage is essential for impact stability during drilling.

Step3. Taper End Machining

| Taper Angle | Small End Diameter (mm) | Tolerance (mm) | Taper Angle | Small End Diameter (mm) | Tolerance (mm) |

|---|---|---|---|---|---|

| 12° | Φ 14.9 | 0 / -0.2 | 7° | Φ 18 | 0 / -0.2 |

| Φ 15.5 | Φ 19 | ||||

| Φ 16 | Φ 20 | ||||

| Φ 16.5 | Φ 21.5 | ||||

| Φ 17.9 | Φ 22 | ||||

| Φ 14.9 | 6° | Φ 18 | |||

| 11° | Φ 17 | 4.76° (4°46′) | Φ 22 / Φ 25 | 0 / -0.2 | |

| Φ 17.5 | – | – | – | ||

| Φ 17.9 | – | – | – | ||

| – | – | – | – |

The taper end is processed using a CNC machining method where the machine rotates while the rod remains stationary.

This technique offers several advantages:

Consistent taper angle

Improved concentricity

Reduced rod deformation

Stable overall quality

Step4. Heat Treatment Technology

Heat treatment is a key process that determines the service life of tapered drill rods. Different methods are applied depending on the steel grade.

Alloy Steel Drill Rod (ZK55SiMnMo)

The shank end is heated and the collar is formed

Overall heat treatment ensures uniform hardness across the shank and rod body

Localized heat treatment (quenching and tempering) is applied to:

Shank end

Slightly tapered end

This two-stage heat treatment improves impact resistance and wear performance in high-stress areas.

Carburized Drill Rod (ZK22CrNi3Mo)

The shank end is heated and the collar is machined

Carburizing process:

Carburizing furnace: 13–14 hours

Tempering furnace: 13–14 hours

Carburizing forms a hard surface layer while maintaining a tough inner core, making the drill rod suitable for heavy-duty drilling conditions.

Comparison with Common Manufacturers

Other manufacturers often complete the carburizing process within 10 hours, while we employ a strictly controlled 20-hour carburizing cycle to ensure the stability of the molecular structure.

This allows for an effective carburized layer depth of 0.6 mm to 1.2 mm, enabling the welding electrode to withstand millions of impacts without breaking.

| Technical Specifications | Standard Industry Process (8-13h) | RHdrill Premium 20-Hour Process | Performance Advantages & Value Addition |

|---|---|---|---|

| Effective Case Depth | 1.0mm – 1.5mm | 2.0mm – 3.0mm+ | Doubled depth significantly extends the wear-resistance limit. |

| Carbon Gradient Transition | Steep gradient; prone to peeling/delamination. | Gentle gradient; high bonding strength. | Eliminates sudden stress changes between brittle layer and ductile core; superior anti-chipping. |

| Core Microstructure | Incomplete transformation; average toughness. | Refined grain structure; high strength & toughness. | Maintains high hardness while delivering exceptional impact fatigue strength. |

| Internal Bore Fatigue Resistance | Prone to micro-cracks under high pressure. | Optimized internal stress distribution. | Dramatically reduces the risk of fractures propagating from inner hole to outer surface. |

| Expected Service Life | 100% (Industry Baseline) | 40% – 60% Increase | Proven performance in ultra-hard rock formations and complex geological conditions. |

| Manufacturing Cost & Input | Lower energy and time cost. | High Investment (Electricity, Gas, Time) | Conclusion: We sacrifice short-term profit to ensure ultimate reliability and lowest cost per meter. |

Step5. Shot Blasting Surface Treatment

Shot blasting removes oxide scale, surface burrs, and residual impurities.

This process improves surface cleanliness and prepares the drill rod for subsequent anti-corrosion treatment.

Step6. Anti-Corrosion Coating

A black paint coating is applied to protect the drill rod from rust and corrosion during storage and transportation.

Step7. Packaging and Marking

Standard export packaging: steel bundles or steel frames

Wooden case packaging available upon request (additional cost)

Custom marking or stamping services available

Why Manufacturing Process Matters for Tapered Drill Rods

A well-controlled production process ensures:

Stable drilling performance

Longer service life

Reduced rod breakage

Lower overall drilling cost

From material selection to final packaging, each step directly influences the reliability of tapered drill rods in real drilling environments.

Certification:Tapter Rod-Quality Inspection

Conclusion

Understanding the manufacturing process of tapered drill rods helps drilling contractors and distributors choose the right products for their applications.

High-quality materials, precise machining, and optimized heat treatment are the foundation of reliable rock drilling tools.

FAQ about Taper Drill Rod

A taper drill rod is a rock drilling tool used to transmit impact energy from the rock drill to the drill bit. The tapered end ensures a secure connection with the drill bit, making it suitable for mining, quarrying, and construction drilling.

The main difference lies in the shank size and impact capacity.

H22 taper drill rods are commonly used for light to medium drilling applications.

H25 taper drill rods are designed for heavier-duty drilling and can withstand higher impact energy.

Common materials include:

ZK55SiMnMo alloy steel, offering good strength and toughness

ZK22CrNi3Mo carburizing steel, which provides a hard surface layer and a tough core for extended service life

Material selection depends on drilling conditions and cost-performance requirements.

Heat treatment directly affects the hardness, toughness, and wear resistance of the drill rod. Proper heat treatment reduces rod breakage, improves drilling efficiency, and significantly extends service life.

Alloy steel drill rods are heat-treated to achieve uniform hardness and are suitable for general drilling conditions.

Carburized drill rods have a hardened surface with a tough inner core, making them ideal for demanding and abrasive rock formations.

Service life depends on rock hardness, drilling parameters, and maintenance. However, rods produced with high-quality materials, precise machining, and proper heat treatment generally offer longer service life and lower operating cost.

Standard export packaging includes steel bundles or steel frames. Wooden case packaging and custom marking services are available upon request.