Table of Contents

Introduction

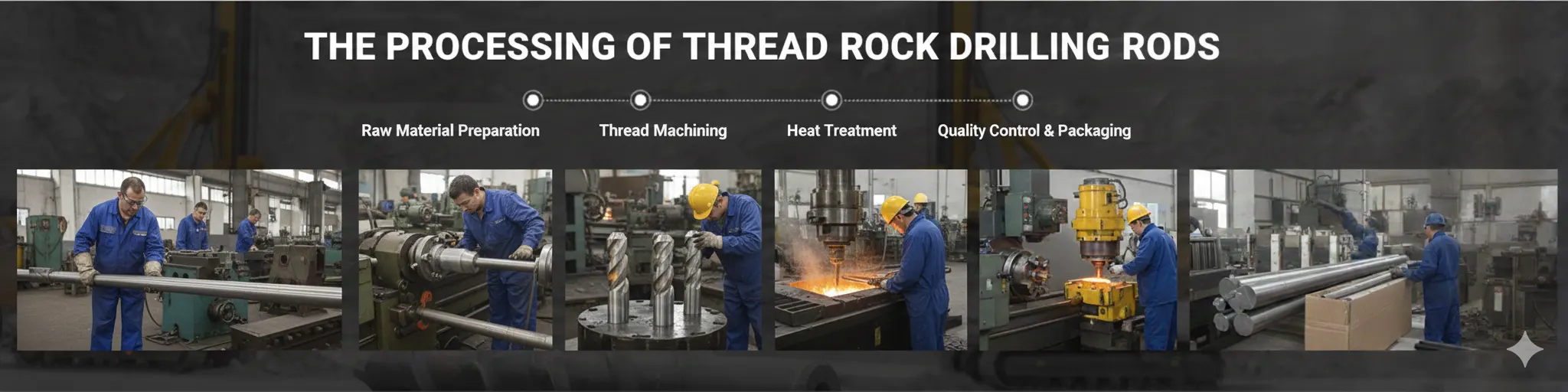

RockHound discover step-by-step processing of threaded rock drilling rods.From premium alloy steel selection to advanced heat treatment and CNC machining.See the technology extend service life and improve drilling efficiency.

Rock Drilling rods are one of the most easily worn parts in a drilling system, and their manufacturing process directly determines construction efficiency.

Step1.Raw Material Processing

RockHound utilize high-quality ZK22CrNi3Mo alloy steel. The Mandrel Rolling process ensures an oval inner hole with a smoother surface, significantly reducing stress concentration compared to conventional hot piercing.

Mandrel Rolling

Process Description:

A 180-200mm square billet or a ≤160mm round billet is used. After impurities are removed by central drilling, an alloy mandrel is inserted. Forming is achieved through multiple pressing passes.

Technical Standards:

Yield ≥80%; inner hole wall smoothness superior to conventional piercing methods; slightly elliptical inner hole shape, beneficial for stress distribution.

Key Indicators:

Compact microstructure and controlled inner hole surface roughness.

Why the "Heart" of RockHound Drill Rods is Stronger: The Mandrel Rolling Advantage

Most manufacturers use standard hot piercing, which can leave microscopic scratches or “blade marks” inside the flushing hole—the exact points where fatigue cracks begin.

We do it differently. By utilizing the Mandrel Rolling (Center-Core Extraction) method, we insert a high-alloy mandrel into the 22CrNi3Mo billet before rolling.

This process ensures:

Mirror-Smooth Inner Walls:

Minimizes stress concentration and prevents premature internal fracturing.

Precision Ovality:

The slightly oval inner bore is engineered to optimize stress distribution during high-frequency percussion.

Superior Material Density:

RockHound rods achieve a higher density and a yield rate of over 80%, ensuring that every centimeter of the rod is as tough as the surface.

The Result: A drill rod that doesn’t just look good on the outside,but is flawlessly engineered from the inside out.

Hot Piercing

Process Description:

The entire billet is heated to a plastic state and formed using a piercing machine.

Technical Standards:

Ensure perfect roundness of the inner hole. Strict monitoring of piercing tool marks and internal scratches is required to prevent stress concentration points.

Disadvantage:

It can cause internal cracks.

Step2.Material Cutting Stage

- Material:Threaded Rock Drilling Rods & Tapered Hexagonal Rods: ZK22CrNi3Mo.

- Precision Cutting to Length: Precision cutting according to order specifications, with length tolerances controlled within specified ranges.

| Product Name | Specifications | Material Grade | Execution Standard | Production Date | Inspection Date | Qty | Judgment |

|---|---|---|---|---|---|---|---|

| Drifting Rod | H25×2000(2500)-R25 | ZK22CrNi3Mo | Q/JSGB6-2011 | 2025-12-02 | 2025-12-05 | 5 PCS | QUALIFIED |

| Chemical Composition Analysis (%) | |||||||

| Element | C (Carbon) | Si (Silicon) | Mn (Manganese) | Cr (Chromium) | Ni (Nickel) | Mo (Molybdenum) | Cu (Copper) |

| Measured (%) | 0.22 | 0.30 | 0.73 | 1.34 | 3.05 | 0.25 | 0.04 |

| Trace Element | S (Sulfur) | P (Phosphorus) | Ti (Titanium) | As (Arsenic) | Sn (Tin) | Al (Aluminum) | Status |

| Measured (%) | 0.014 | 0.01 | 0.003 | 0.005 | 0.004 | 0.026 | PASS |

Step3.Raw Material Straightening

- Purpose: To eliminate bending stress in the raw material.

- Standard: To ensure concentricity of drilling during subsequent machining processes and reduce dynamic balance errors.

Step4.Threading & Forming

Friction Welding

Prepare the machined joint and connect it to the rod body.The rod body and drill pipe joint are welded together using friction welding.The inner and outer rolled edges of the connection are removed.

Note: Strict control of upsetting pressure, rotation speed, and friction time is required to ensure the mating surface reaches the strength of the base material.

This step is not required for guide drill rods and drill rods larger than 52mm, as a large inner hole does not affect water flow.

Forging Upsetting

Different process from friction welding.To ensure the thread strength exceeds the rod body for heavy-duty applications.

- Application: Suitable for large-diameter threads (large threads larger than the rod diameter) or internal thread machining needs.

- Standard: The material is formed by extrusion through a 250-ton forging press after high-temperature heating, followed by peeling, shaping, threading, and other processes.

Step5.Appearance Treatment

- Standard: Applicable to rods with a diameter ≤ 52mm. Both inner and outer rolled edges must be completely removed to prevent erosion and wear or blockage of the slag discharge hole during use.

- Note: For rods with a diameter of 52mm or larger, rolling is not required due to the larger diameter.

Step6.Heat Treatment

Equipment of Heat Treatment

- Carburizing furnaces (8 in total):Which 5 furnaces have a total length of 7m (The longest drill rod that can be processed is 6.5m).

- Homogenization principle: Products of the same batch and specifications must be processed simultaneously.Mixed loading is strictly prohibited to ensure the consistency of process curves (temperature, carbon potential, time).

Heat Treatment Cycle Standard:

Total Aging Time:

20-hour standard cycle (covering carburizing, quenching, tempering, and controlled cooling).

Technical Advantages:

Compared to the industry standard of 8-10 hours, Guigang’s process takes 12-14 hours. This longer cycle ensures a thicker carburized layer and a gentler carbon concentration gradient.

Performance Objectives:

A balance between extremely high wear resistance and core high toughness, enhancing overall fatigue resistance.

Why Heat Treatment is the "Soul" of a Drill Rod

This is a core factor determining the wear resistance and fatigue strength of rock drill rods.

The most critical stage in the processing of rock drilling rods is undoubtedly heat treatment. To withstand the high-frequency impact and rotational torque in harsh mining environments, a rod must be “hard outside but tough inside.”

Through Full-length Carburization, we diffuse carbon into the steel surface at high temperatures, creating a wear-resistant skin. This process ensures that the threads don’t strip and the rod doesn’t snap under extreme pressure, directly reducing your downtime and replacement costs.

| Technical Specifications | Standard Industry Process (8-13h) | RockHound 20-Hour Process | RockHound Advantage |

|---|---|---|---|

| Effective Case Depth | 1.0mm – 1.5mm | 2.0mm – 3.0mm+ | Doubled wear resistance in abrasive rock; significantly extends bit life in high-quartz and ultra-hard formations |

| Carbon Gradient | Steep (prone to peeling) | Gentle / Smooth | Prevents “brittle snapping” and chipping; eliminates sudden stress risers between hardened case and tough core |

| Core Microstructure | Moderate toughness | Refined Grain Structure | Exceptional impact fatigue resistance; maintains high surface hardness while delivering superior toughness under cyclic loading |

| Service Life | 100% (Baseline) | 140% – 160% | 40–60% increase in proven service life; delivers lower cost per meter and higher rig uptime in demanding geological conditions |

20-Hour Deep Carburization

In the world of rock drilling, “time in the furnace” equals “life in the hole.” While the industry average for heat treatment is only 8 to 12 hours, our premium rods undergo a rigorous 20-hour deep carburization cycle.

This extended process isn’t just about extra time; it’s about precision chemistry. By doubling the treatment duration, we achieve:

Deeper Case Hardness:

A significantly thicker carburized layer that stands up to the most abrasive rock formations.

Optimized Carbon Gradient:

A smoother transition from the hard outer shell to the tough, ductile core. This prevents the “brittle snapping” common in cheaply treated rods.

Maximum Fatigue Resistance:

Our 20-hour cycle allows for superior stress relief and molecular stabilization, drastically reducing your “Cost per Meter” (CPM).

The Bottom Line: We invest more in electricity, gas, and time so that you spend less on replacements and downtime.

Comparison with Common Manufacturers

Other manufacturers often complete the carburizing process within 10 hours, while we employ a strictly controlled 20-hour carburizing cycle to ensure the stability of the molecular structure. This allows for an effective carburized layer depth of 0.6 mm to 1.2 mm, enabling the welding electrode to withstand millions of impacts without breaking.

| Technical Specifications | Standard Industry Process (8-13h) | RHdrill Premium 20-Hour Process | Performance Advantages & Value Addition |

|---|---|---|---|

| Effective Case Depth | 1.0mm – 1.5mm | 2.0mm – 3.0mm+ | Doubled or greater case depth dramatically extends wear resistance and service life in abrasive and high-impact rock drilling conditions. |

| Carbon Gradient Transition | Steep gradient; prone to peeling and delamination under cyclic loading. | Gentle / smooth gradient; superior bonding strength | Eliminates abrupt stress concentrations at the case-core interface → significantly improved resistance to chipping, spalling, and layer separation. |

| Core Microstructure | Incomplete phase transformation; moderate toughness. | Fine / refined grain structure; high strength & toughness | Achieves exceptional balance of surface hardness and core impact fatigue resistance — ideal for demanding top hammer and DTH applications. |

| Internal Bore Fatigue Resistance | Susceptible to micro-crack initiation under high-pressure flushing. | Optimized compressive stress distribution | Greatly reduces risk of internal crack propagation to the outer surface, enhancing reliability in high-pressure and long-duration drilling. |

| Expected Service Life | 100% (Industry Standard Baseline) | 40% – 60% Increase | Proven in ultra-hard formations (granite, quartzite) and complex geology — delivers substantially lower cost per meter drilled and higher rig uptime. |

| Manufacturing Cost & Input | Lower energy, gas, and cycle time requirements. | High investment (extended electricity, gas, 20-hour cycle) | Strategic Conclusion: Premium long-cycle carburizing process prioritizes maximum durability and lowest total drilling cost over short-term production savings. |

Step7.Fully Automatic Straightening

Currently capable of calibrating lengths up to 2m.Shougang Guiyang Special Steel, as RockHound’s supply chain partner, plans to adopt a 6m straightening machine in 2026.

Step8.Surface Treatment

Shot Peening:Removes oxide scale and generates residual compressive stress on the rod surface, further enhancing fatigue resistance.

Grinding and Finishing the Middle Section of the Bar.

Step9.Surface Anti-Corrosion Treatment

- Phosphating: Improves chemical protection (optional).

- Electrostatic spraying: External surface treatment, commonly using black anti-rust paint, emphasizing visual quality.

- Overall wax impregnation (≤4.5m): Impregnation of the entire shaft, both inside and out. Advantages: Extremely strong corrosion resistance to the inner bore; rust prevention is superior to painting.

- Oil impregnation (≤6m): Primarily for rust protection of the shank and tip (threaded area).

Step10.Packaging & Warehousing

- Framed packaging:If wooden crate packaging is required (custom-made), confirmation with logistics is necessary (time and cost).

- Marking Instructions: Laser marking or steel stamping is a value-added process; specifications need to be confirmed separately.

Why Choose RockHound Drilling Rods?

In high-intensity drilling, your equipment is only as strong as its weakest link. Rock drilling rods are the most frequently replaced components in any drilling system. At RockHound, we don’t just manufacture rods; we engineer durability.

Through premium material selection and industry-leading thermal processing, we deliver a lower Cost per Meter (CPM) and significantly reduced downtime.

The "Heart" of the Rod: Mandrel Rolling Advantage

Mirror-Smooth Inner Walls:

Eliminates internal scratches to prevent premature fracturing.

Precision Ovality:

Our engineered slightly oval bore optimizes stress distribution during high-frequency percussion.

Superior Density:

A higher material density ensures the rod is as tough at its core as it is on the surface.

The "Soul" of the Rod: 20-Hour Deep Carburization

Heat treatment is the single most critical factor in a rod’s lifespan. While the industry average for heat treatment is only 8 to 12 hours, RockHound premium rods undergo a rigorous 20-hour deep carburization cycle.

The Bottom Line: We invest more in electricity, gas, and time so that you spend less on replacements and maintenance.

Premium Material: ZK22CrNi3Mo Alloy Steel

We start with the best. Our rods are forged from ZK22CrNi3Mo high-grade alloy steel, specifically chosen for its high nickel and molybdenum content.

High Fatigue Strength:

Designed to withstand millions of high-impact blows.

Precision Straightening:

Every rod undergoes automatic straightening to eliminate bending stress and ensure perfect concentricity.

Advanced Threading & Surface Protection

Friction Welding & Forging:

We use 250-ton forging presses for large-diameter threads to ensure the connection point is stronger than the rod body itself.

Shot Peening:

This process creates residual compressive stress on the surface, further shielding the rod against fatigue.

Full-Length Wax Impregnation:

Unlike simple painting, our rods (up to 4.5m) are fully submerged in wax. This provides extreme corrosion resistance for the inner bore, preventing rust from the inside out.

Conclusion:Reduce Downtime & CPM

The manufacturing of a rock drilling rod is more than just shaping steel; it is a balance of metallurgy and mechanical science. At our facility, every step of the processing—from the selection of 22CrNi3Mo alloy and the precision of Mandrel Rolling to our industry-leading 20-hour deep carburization cycle—is designed with one goal in mind: reducing your downtime.

While others may cut corners by shortening heat treatment times or using standard hot piercing, we believe that quality is the only way to lower your Cost per Meter (CPM). Our commitment to full-length wax dipping and automated straightening ensures that every rod delivered to your site is ready to withstand the toughest geological conditions.

Choosing RockHound drill rods means choosing reliability, a longer fatigue life, and a smarter investment for your drilling operations.

FAQ

Integral Rods: Best for hand-held, shallow-hole drilling (22mm–40mm). They offer zero energy loss at the joint.

Tapered Rods: Ideal for granite/marble quarrying and small-hole mining. They are cost-effective as you only replace the bit.

Threaded Rods: The go-to for deep-hole drilling and underground production. They allow for extensions and handle high-frequency impact.

MF rods feature an integrated coupling at one end. This design allows for faster handling, tighter connections, and eliminates the need for separate couplings, making them perfect for high-speed drifting and long-hole production.

Most manufacturers use hot piercing, which can leave microscopic scratches inside the flushing hole—the starting point for fatigue cracks. Our Mandrel Rolling (Center-Core Extraction) ensures:

Mirror-smooth inner walls to minimize stress concentration.

Precision ovality for better stress distribution during high-frequency percussion.

While most suppliers stop at 8-12 hours, our 20-hour deep carburization provides:

A significantly thicker wear-resistant layer (2.0mm–3.0mm+).

A smoother carbon gradient that prevents the surface from "peeling" or "snapping" under extreme pressure.

Up to 40%–60% increase in total service life.

We exclusively use premium ZK22CrNi3Mo or 23CrNi3Mo alloy steel. This high-nickel and high-molybdenum grade offers the perfect balance of core toughness and surface hardness.

Follow these four "Golden Rules":

Lubricate Threads: Always use high-quality thread grease to prevent "cold welding."

Check Straightness: A bent rod creates uneven stress. Inspect rods before every shift.

Keep Bits Sharp: A dull bit reflects shockwaves back into the rod, causing fatigue.

Protect the Bore: Our rods are wax-impregnated to prevent internal rust—ensure you flush the hole properly during operation.

Discoloration is a sign of overheating. Stop drilling immediately and allow the rod to cool naturally. Never quench it in water, as this will make the steel brittle and lead to instant snapping.

Yes! We provide precision cutting to your specific length requirements. We also offer laser marking or steel stamping for brand identification, though these are value-added services that should be confirmed during the order process.

We take anti-corrosion seriously. All rods (up to 4.5m) undergo full-length wax dipping, which offers superior rust protection compared to standard painting. For long-distance shipping, we provide framed packaging or custom wooden crates upon request.