Table of Contents

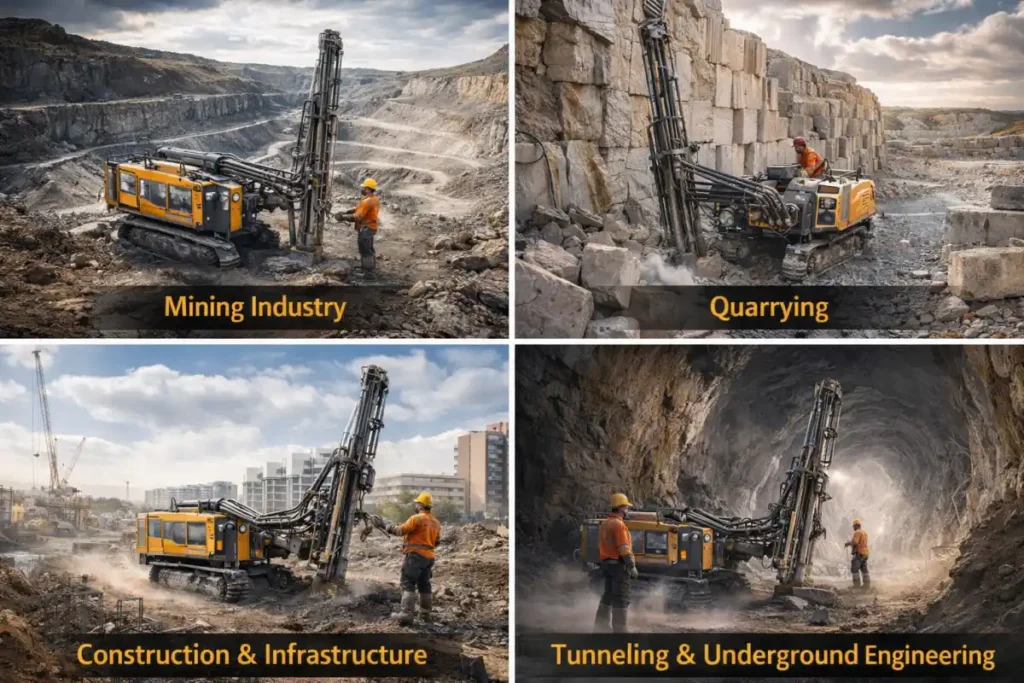

Top hammer button bits are one of the most commonly used rock drilling tools in mining, quarrying, construction, and tunneling. Known for their high penetration rate and excellent durability, they play a key role in top hammer drilling systems.

In this guide, we’ll explain what a top hammer button bit is, how it works, its applications, maintenance tips, and answer the most frequently asked questions to help you choose and use the right button bit for your drilling project.

What Is a Top Hammer Button Bit?

A top hammer button bit is a rock drilling bit designed for top hammer drilling rigs, where impact energy is generated at the top of the drill string and transmitted through drill rods to the bit.Top hammer button bits are widely used as rock drilling button bits for medium to hard rock formations.

The bit typically consists of:

A high-strength alloy steel bit body

Tungsten carbide buttons (spherical, ballistic, or semi-ballistic)

Flushing holes for air or water circulation

Compared with DTH bits, top hammer button bits are ideal for shorter hole depths, faster drilling cycles, and surface or underground drilling operations.

Key characteristics:

High penetration rate

Excellent impact resistance

Suitable for hard and abrasive rock formations

Easy to regrind and maintain

How Does a Top Hammer Button Bit Work?

Understanding how a top hammer button bit works helps improve drilling efficiency and extend bit service life.In short, a top hammer button bit works through the combination of impact, rotation, and efficient flushing.

Impact Energy Transmission

In top hammer drilling, the rock drill generates high-frequency impact energy. This energy travels through the drill rod and reaches the top hammer button bit(typically 2,000–5,000 blows/min,200–500 joules per blow).

Rock Breaking with Tungsten Carbide Buttons

When the impact reaches the bit, the tungsten carbide buttons strike the rock surface, creating cracks and fractures. These buttons are specifically designed to withstand high impact and abrasion.

Rotation for Efficient Cutting

At the same time, the drill string rotates, allowing the button bit to hit fresh rock surfaces continuously. This rotation ensures(usually 50–150 rpm, the bit rotates ~5–15° per blow):

Uniform button wear

Stable penetration

Improved drilling accuracy

Flushing of Rock Cuttings

Air or water flows through the flushing holes to remove rock cuttings, cool the bit, and prevent bit jamming. Proper flushing is critical for top hammer drilling performance.

This combined action enables fast penetration, stable drilling, and long bit service life.

Applications of Top Hammer Button Bits

Top hammer button bits are widely used across multiple industries and drilling scenarios.

These button bits perform best in granite, basalt, limestone, and other hard or abrasive rock formations, making them a reliable choice for professional drilling contractors.

Mining Industry

Production drilling

Blast hole drilling

Exploration drilling

Quarrying

Bench drilling

Dimension stone extraction

Aggregate production

Construction & Infrastructure

Foundation drilling

Road and bridge construction

Slope stabilization

Tunneling & Underground Engineering

Face drilling

Rock bolting

Anchoring

How to Maintain a Top Hammer Button Bit

Proper top hammer bit maintenance can significantly reduce drilling costs and extend bit life.

1.Daily/After Each Use Cleaning and Inspection

Clean thoroughly after every shift or drilling operation: Remove rock dust, cuttings, debris, and mud from the bit face, buttons, flushing holes, and threads using compressed air, water, or a wire brush. Blocked flushing holes reduce cooling and cuttings removal, leading to overheating and faster wear.

Inspect visually:

- Check carbide buttons for flattening, rounding, chipping, cracking, or mushrooming.

- Look at the bit body (face and gauge) for cracks, wear, or steel wash (erosion around buttons).

- Examine threads for damage, galling, pitting, or seizing — apply anti-seize lubricant on threads before re-use or storage.

- Measure button protrusion/height if possible (many manufacturers provide wear limits).

Signs it’s time to regrind (don’t wait until severely worn):

- Buttons are flat or mushroomed (reduced penetration rate).

- Increased vibration or “chatter.”

- Slower ROP (rate of penetration).

- More dust or smaller cuttings (re-drilling same material).

- Steel face starting to contact rock bottom.

2.Regular Regrinding (Sharpening) — The Most Important Maintenance

Regrinding restores the original button profile (spherical, ballistic, etc.), restores sharp edges, and can extend bit life 3–10 times compared to non-ground bits.

When to grind: Typically after 200–600 meters drilled (depends on rock abrasiveness — softer rock allows longer intervals; very abrasive rock needs frequent grinding). Some modern bits (e.g., Sandvik Autobit) extend the first interval significantly.

How it’s done:

- Use diamond grinding cups/wheels on handheld pneumatic grinders (e.g., Sandvik, Epiroc, or CME models) or semi-automatic stationary grinders for high-volume shops.

- Grind each button to match the original shape and protrusion — follow manufacturer guidelines for angle and depth.

- Cool with water during grinding to avoid overheating the carbide.

- After grinding, clean and inspect again.

Frequency example (from real operations): First regrind after ~400 m, second after another 200–300 m.

- Proper regrinding prevents button chipping (most common failure mode when over-drilled).

3.Proper Operation to Reduce Wear

- Match bit design (button shape, face contour, thread type) to rock conditions.

- Optimize drilling parameters: Correct feed pressure, rotation speed (usually 50–150 rpm), impact energy, and flushing volume/pressure — too much or too little causes excessive wear.

- Avoid free hammering (impacting without rock contact) — it can cause button loss or cracking.

- Use good flushing (air or water) to clear cuttings quickly.

4.Storage and Handling

- Store in a dry, clean place to prevent rust or corrosion.

- Avoid dropping or banging the bit.

- Apply thread lubricant before connecting to rods.

- Rotate bits in inventory to use oldest first.

Good maintenance ensures your top hammer button bits deliver consistent performance throughout their service life.

Quick Reference Table: Maintenance Checklist

| Task | Frequency | Why It Matters | Tools/Notes |

|---|---|---|---|

| Clean bit | After each use/shift | Prevents clogging & overheating | Air/water, brush |

| Visual inspection | Daily / after each hole | Catch wear early | Look for flat buttons, thread damage |

| Regrind buttons | Every 200–600 m (typical) | Restores sharpness, extends life 3–10× | Diamond cup grinder, follow profile |

| Thread lubrication | Before every connection | Prevents seizing/galling | Anti-seize compound |

| Replace bit | When buttons crack/lost, body washed, or after multiple regrinds | Safety & efficiency | Reach manufacturer wear limits |

Top Hammer Button Bit vs DTH Hammer

The top hammer button bit works by receiving rapid, powerful shock waves from the surface hammer, crushing rock with super-hard carbide buttons, while rotation and air/water flushing keep the hole clean and progressing. It’s a fast, efficient system for many surface and underground drilling applications!

| Feature | Top Hammer Button Bit | DTH (Down-The-Hole) Hammer |

|---|---|---|

| Hammer location | Top of drill string | Directly behind the bit |

| Energy transfer | Through rods (loses efficiency in deep holes) | Direct at bit → better deep hole performance |

| Typical hole depth | 3–30 m (extension rods) | 10–100+ m |

| Hole diameter | 32–127 mm | 89–254+ mm |

| Primary breaking mechanism | High-frequency impact + rotation | Lower frequency but higher energy impact |

| Best for | Short-medium holes, high speed, smaller diameters | Deep holes, straighter bore |

Conclusion

Top hammer button bits are essential tools for efficient rock drilling. By understanding how top hammer button bits work, choosing the right design, and following proper maintenance practices, drilling operators can achieve higher productivity and lower cost per meter.

If you are looking for reliable top hammer drilling button bits, selecting the right supplier and bit design is just as important as correct operation.

FAQ

Top hammer button bits are used for rock drilling in mining, quarrying, construction, and tunneling, especially in medium to hard rock formations.

Spherical button bits offer superior wear resistance and longer service life

Ballistic button bits provide faster penetration in softer rock but wear faster

Yes. Most high-quality tungsten carbide button bits can be regrinded multiple times to extend service life.

Consider:

Rock hardness and abrasiveness

Required hole diameter

Drill rig power

Desired balance between penetration rate and bit life

Common reasons include:

Overfeeding

Insufficient flushing

Incorrect bit selection

Late regrinding