In the world of Top Hammer Rock Drilling, the coupling sleeve might seem like a simple component, but it is the critical “joint” of the entire drill string. Its quality directly determines the efficiency of energy transfer and the lifespan of your drill rods and shank adapters.

In this guide, RockHound’ll break down why the design matters, the different types available, and how to select the right one for your mining or construction project.

What is a Coupling Sleeve?

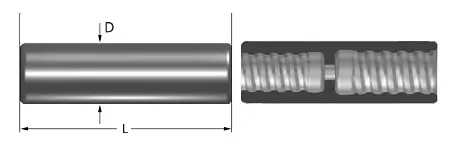

The primary role of a coupling sleeve is to connect the Shank Adapter to the Drill Rod, or to connect two drill rods together. However, its engineering goes deeper:

Efficient Energy Transfer: It ensures that the high-frequency impact energy from the rock drill’s piston is transmitted through the drill string to the bit with minimal loss.

Precision Alignment: It maintains the axial alignment of the drill string, preventing hole deviation and reducing bending stress on the threads.

Stress Distribution: High-quality sleeves are designed to dissipate the intense shock waves, preventing premature thread stripping or “fretting.”

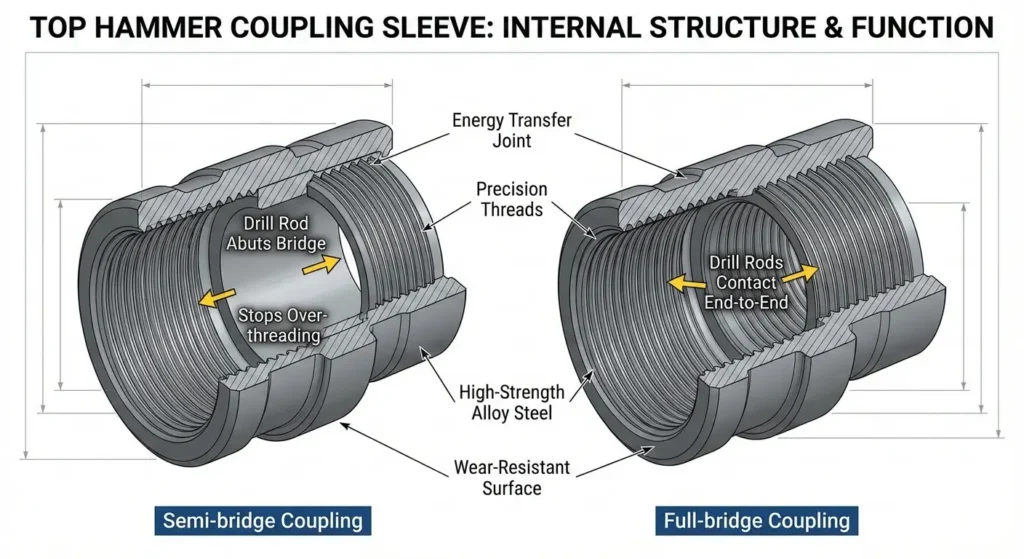

Structure & Function of Top Hammer Coupling Sleeve

Main Types of Coupling Sleeves

Choosing the right internal structure is vital for different drilling conditions. There are three industry-standard designs:

Semi-Bridge Coupling (Industry Standard)

This is the most popular type for standard extension drilling. It features a non-threaded “bridge” in the center.

Function: The drill rods butt against the middle bridge, preventing the rods from over-threading into the sleeve.

Best For: General production drilling where stability and easy uncoupling are priorities.

Full-Bridge Coupling

A full-bridge sleeve is threaded throughout its entire length but includes a central stop.

Function: It allows the drill rods to make end-to-end contact in the center of the sleeve.

Best For: Heavy-duty applications requiring high torque transmission. The end-to-end contact helps the rods take the brunt of the impact, protecting the sleeve’s own threads from excessive tension.

Adapter Couplings (Crossover Sleeves)

Used when you need to connect components with different thread sizes (e.g., an R32 shank to a T38 drill rod).

Function: Acts as a converter, providing flexibility in managing your drill tool inventory.

Specifications & Thread Compatibility

| Thread Type | Connection Style | Common Applications |

|---|---|---|

| R25, R28, R32 | Semi-bridge | Light-duty drifting and tunneling; small to medium hole sizes in underground mining and civil tunneling projects |

| T38, T45, T51 | Semi / Full-bridge | Bench drilling, production blasting, quarrying, and surface mining; medium to large diameter holes with high energy transfer |

| ST58, GT60 | Full-bridge | Large-hole deep drilling, high-torque applications, longhole stoping, and demanding surface / underground operations requiring maximum power transmission |

| Adapter / Crossover | Custom | Connecting different thread sizes (e.g., R32 to T38, T45 to GT60); transitional use when mixing rod/hammer/bit systems or upgrading equipment |

Compatibility is non-negotiable. RockHound provide coupling sleeves in all standard international thread profiles:

R-Series (Rope Threads): R22, R25, R28, R32, R38.

T-Series (Trapezoidal Threads): T38, T45, T51.

GT/ST-Series: ST58, ST68, GT60 (Designed for large-hole deep drilling).

How to Choose the Right Coupling Sleeve?

For an independent station operator, educating the customer on Value vs. Price is key. Here is what defines a premium coupling:

Material Grade:

We use premium high-strength alloy steel (equivalent to heavy-duty mining grades) to ensure the sleeve can withstand millions of high-frequency impacts.

Advanced Heat Treatment:

Look for Carburized (Case-Hardened) sleeves. Carburization creates a hard, wear-resistant outer shell while maintaining a tough, flexible core to prevent brittle fracturing.

CNC Precision Machining:

Accurate thread geometry is essential. Even a 0.5mm deviation can cause “thread play,” leading to overheating and total tool failure.

Pro Tip: If your customers complain about “stuck” couplings, recommend switching to a Semi-bridge design or using high-quality Thread Grease to prevent cold-welding under high pressure.

Maintenance for Longer Service Life

Inspect Threads Regularly:

If the thread profile looks “flat” or thin, replace the sleeve immediately to avoid damaging your more expensive drill rods.

Lubrication:

Never join threads dry. Always use a copper or graphite-based thread lubricant.

Monitor Temperature:

Excessive heat at the coupling joint usually indicates a loose connection or worn threads.

Why Choose RockHound Coupling Sleeves?

Premium Alloy Steel:

Manufactured with high-grade 22CrNi3Mo steel to withstand extreme impact and rotation torque.(View:Coupling Sleeve Manufacturing Process)

Carburized Hardening:

Advanced 20-hours heat treatment ensures a wear-resistant surface and a tough core to prevent fractures.

CNC Precision Threads:

Perfect fit with Atlas Copco, Sandvik, and other major brands to prevent “loose joints” and energy loss.

Extended Service Life:

Field-tested to last 15-20% longer than standard aftermarket alternatives.(View:Field Test Report: MF T38-R32 Drill Rods & Bits at Iron Mine)

Trust & Reliability

Global Logistics:

We ship to over 50 countries with optimized freight for heavy drill tools.

Technical Support:

Not sure which bridge type you need? Our engineers are available for a free consultation.

Quality Guaranteed:

ISO 9001 & ISO 14001 & ISO 45001 certified manufacturing process.(View:About-us)

FAQ

The coupling sleeve acts as the "bridge" in a top hammer drill string. Its main roles are to connect the shank adapter to the drill rod (or connect multiple rods), ensure precise axial alignment, and facilitate the efficient transfer of impact energy from the rock drill's piston to the drill bit.

It depends on your drilling conditions:

Semi-Bridge: Best for standard applications. It features a middle bridge to prevent the rods from over-threading, making it easier to uncouple tools.

Full-Bridge: Ideal for high-torque or heavy-duty drilling. It allows the drill rods to make end-to-end contact in the center, which helps the rods absorb more of the impact energy directly, protecting the sleeve's threads from tension.

An Adapter Coupling (also known as a crossover sleeve) is used when the thread on your shank adapter does not match the thread on your drill rods (e.g., connecting an R32 shank to a T38 rod). It allows you to use different components of a drill string without replacing the entire set.

Top hammer tools face extreme friction and high-frequency impacts. Carburization creates a high-hardness, wear-resistant outer layer while maintaining a tough, ductile core. This prevents the threads from wearing down too quickly and protects the sleeve from brittle fracturing under heavy loads.

Yes. High-quality coupling sleeves are manufactured according to international thread standards (such as R32, T38, T45, etc.). As long as the thread profile and size match, they are fully interchangeable with components from major global manufacturers.

This is often caused by "cold-welding" or excessive heat due to:

Lack of proper thread grease (lubrication).

Using worn-out threads that allow too much "play" or movement.

Over-tightening during high-torque drilling without a bridge stop. Tip: Always use copper or graphite-based thread lubricant to prevent this.

You should replace the sleeve when the internal threads show visible signs of thinning, flattening, or pitting. Using a worn sleeve will cause energy loss and can lead to the "stripping" of the threads on your more expensive drill rods or shank adapters.