Unlike standard rods, our Mandrel Rolling process eliminates internal scratches, stopping fatigue cracks before they start.

High-nickel, high-moly steel provides the ultimate balance of surface hardness and high-impact toughness.

Manufacturing a rock drilling rod is a balance of metallurgy and mechanical science. From the precision of our CNC machining to our full-length carburization, every step is designed to ensure that when your rig is running, our rods are performing. Stop paying for downtime. Choose RockHound for reliability in every meter.

We bake our rods for 20 hours (double the industry standard). Result? A thicker wear-resistant skin and a core that won’t snap.

Full-length wax impregnation protects the flushing hole from rust and erosion, extending shelf life and performance.

| Element | C | Si | Mn | Cr | Ni | Mo |

|---|---|---|---|---|---|---|

| Measured | 0.22 | 0.30 | 0.73 | 1.34 | 3.05 | 0.25 |

| Metric | Standard | RockHound |

|---|---|---|

| Case Depth | 1.5mm | 3.0mm+ |

| Gradient | Steep | Gentle |

| Service Life | 100% | 160% |

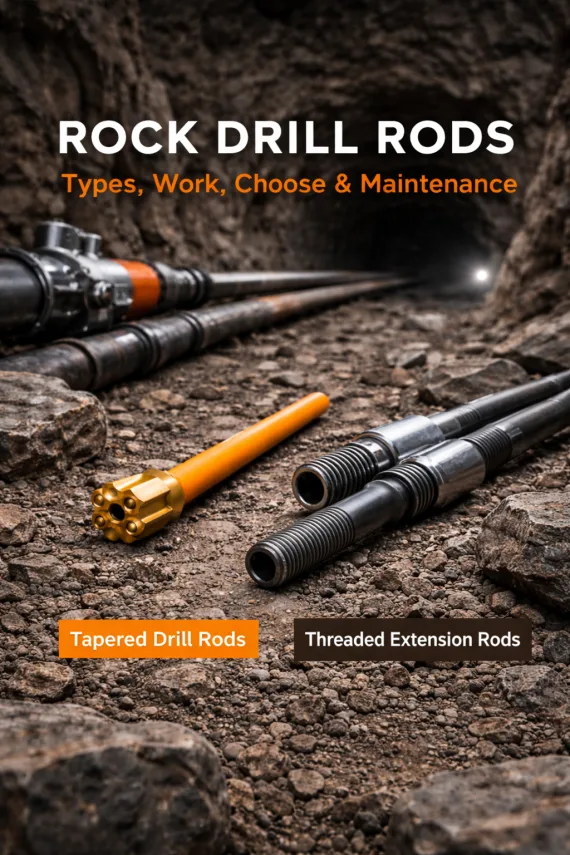

In the demanding world of mining, tunneling, and quarrying, the rock drill rod is the unsung hero that bridges the gap between the power of the rock drill and the impact of the bit.

Choosing the right rod isn’t just about compatibility; it’s about maximizing energy transfer and minimizing downtime.

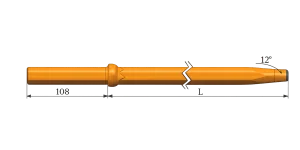

Energy Transfer: The piston of the rock drill strikes the shank (or the rod itself), sending a shockwave through the steel to the bit.

Flushing: Most rods feature a hollow center (flushing hole) to allow water or air to pass through, clearing rock chips from the hole to prevent jamming.